We attach great importance to customers' needs for product quality and rapid production.

We always insist that meeting customers' needs is to realize our value!

+86 133 9281 9446

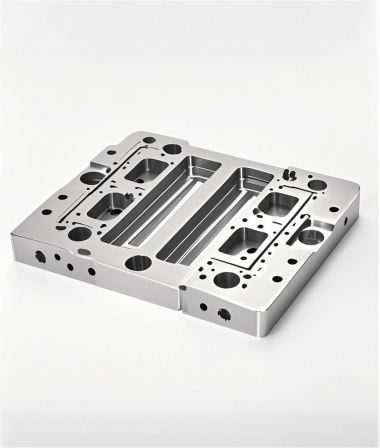

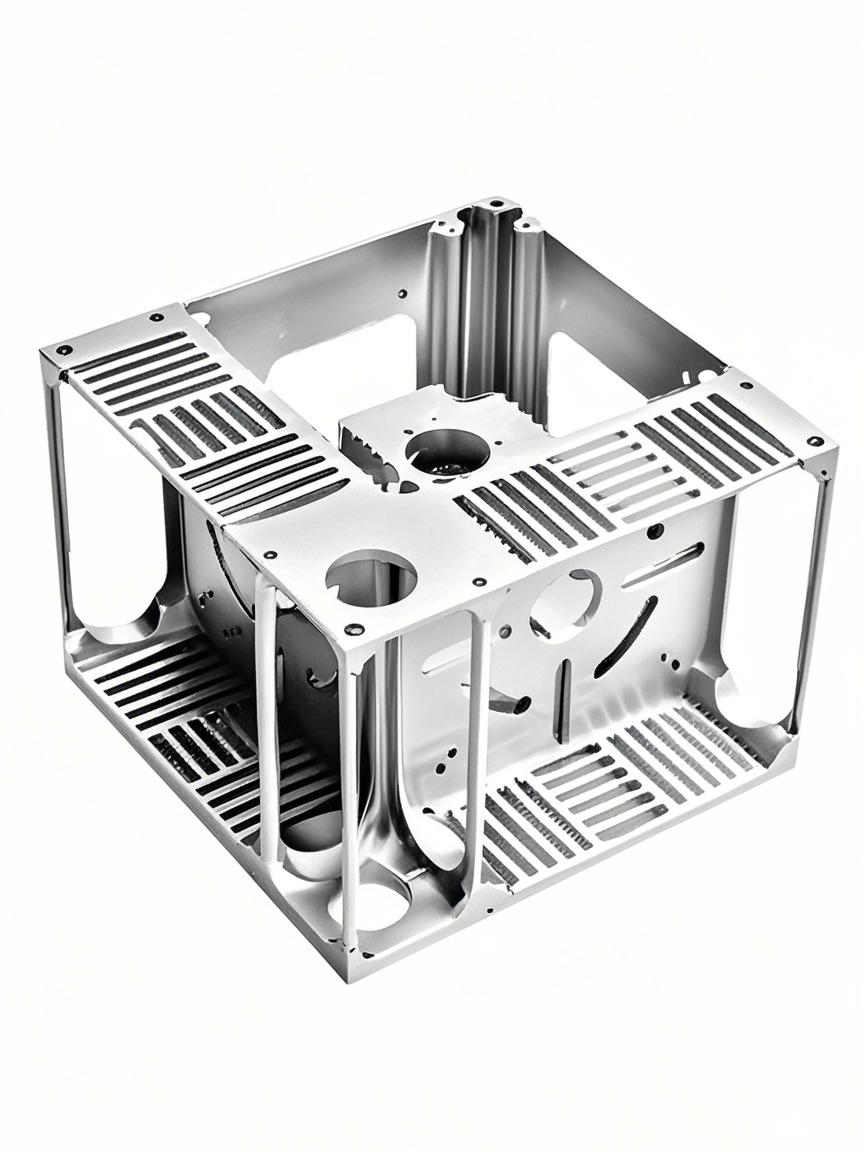

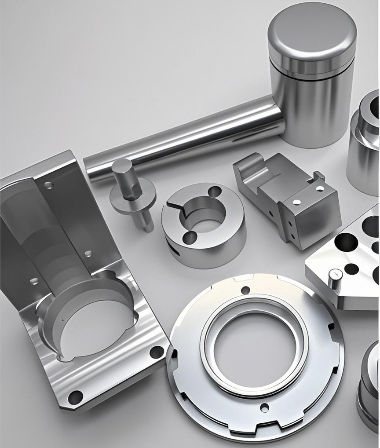

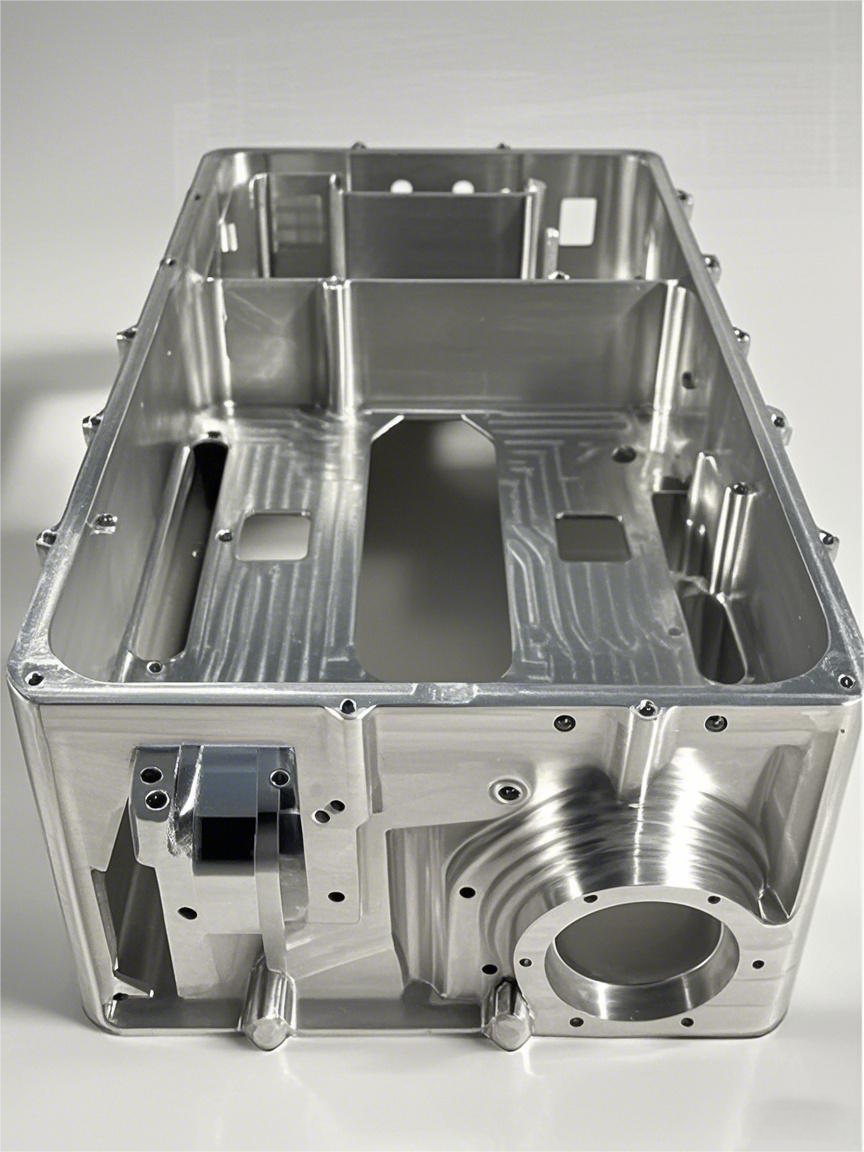

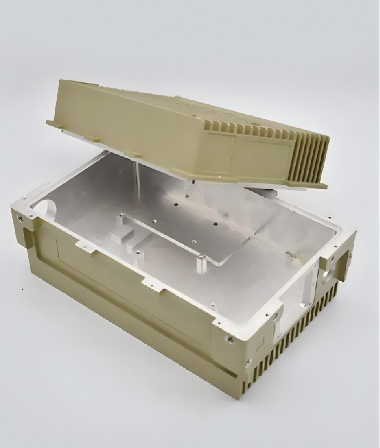

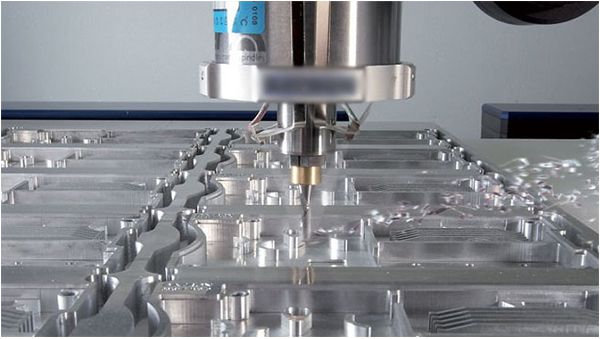

Kaierwo provides a variety of precision CNC machining services including milling, turning, EDM, wire EDM and surface grinding with precision 3-.4- and 5-axis CNC machining centers, combined with other advanced capabilities and our experienced team. We can handle all types of CNC machining parts in both metal and plastic materials,such as aluminum,Stainless steel, Brass,ABS,ABS+PC,Nylon.

Kaierwo CNC Machining Services Processing:

CNC Turning/ 5 Axis Machining/ CNC Milling/ Surface Finishing/ 3D Printing Service/ Rapid Tooling

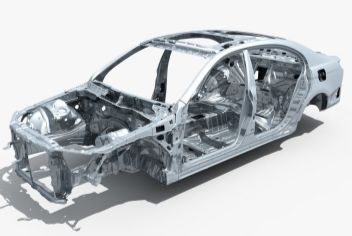

Kaierwo CNC machining services are provided to industries such as automotive, aerospace, medical, and electronics. With over 40,000 CNC projects completed and 14 years of manufacturing experience, we can offer clients the most flexible customized production solutions.

If you are looking for a CNC machining service company, please contact us!

Made to order from 1 to 10,000 pieces on demand

One-on-one support serviceOResponse within 12 hours

In-house machine shop, 24/7 operations, Quick turnaround

Tight tolerance +0.05mm Surface roughness Ra0.2μm

ISO 9001:2015 certified100% part inspection

Kaierwo CNC machining Center Includes the CNC Cutting, CNC Milling and CNC Turning process. Our CNC Cutting and milling process wIth advance software and quick change cutters alows for complicate internal and external 3D geo meuries Shape metal to be Generated in a rapid delivery time, and our CNC machining capaclty is avallable for one plece prototype through to hundred and even hundred-thousands Pleces productlon . Our general tolerance for CNC Metal cutting, milling and turning is DIN-2 /68-1-ine, We are wling to fllw your 2D assembly tolerance on every part from your project and provide you the best poss ble preclslon tolerance.

With Kaierwo's high-precision CNC lathes and talented engineers with 14 years of experience in CNC turning for parts manufacturing, the latest high-precision machines and tools, you can get a quick quote in as little as 3 hours, and your project can be sent out in 5 days or even less!

EDM short for ElectrIcal dlscharge machinlng Is a process for Metal square pocket holes, CNC unreachable under cuts and Internal cavltles making, the EDM process IS to make the metal dlfcult and Imposslble area out In shape by bath erodIng.

How to Select CNC Machining Services?

You can set up a consultation and planning phase with our team of additive manufacturing experts.We wil assistance in finding which CNC Machining Services is the right fit for you!

CNC Machining Solutions

Rapid Prototyping

1-100 Quantity, with in 3 days by 3D printing,CNC machining,Vacuum casting,Sheet Metal Fabrication etc.

Low Volume Manufacturing

100-10000 pieces, CNC machining, Vacuum Casting ,Sheet Metal Fabrication, Injection Molding, die casting etc.

Mass Production

10000 or more, CNC machining, Precision Machining, injection molding, die casting,Sheet Metal Stamping etc

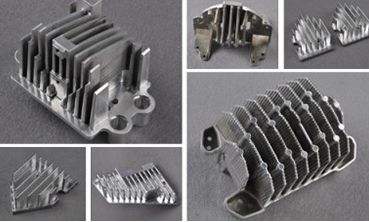

Products Made With Aluminum CNC Machining

Aluminum 6061

Aluminum 6061 is a high-quality aluminum alloy product produced through a heat-treated pre-stretching process.

Advantages

High strength heat treatable alloy

Good mechanical properties

Good workability

Easy to process, good wear resistance

Good corrosion and oxidation resistance

Disadvantages

The strength decreases significantly after welding and the wear resistance is poor

Aluminum 6063

6063 is a special aluminum alloy known for its high strength and ease of welding.

Advantages

Excellent processing performance

Good corrosion resistance

Comprehensive mechanical properties Balanced welding performance

Excellent environmental protection and cost performance

Disadvantages

Medium strength, not suitable for high load scenarios,

Limited high temperature performance

Average cutting performance

Aluminum 6082

Aluminum 6082 belongs to Al-Mg-Si series heat-treatable and strengthened aluminum alloy.

Advantages

Good weldability and machinability

Combination of medium strength and light weight

Outstanding corrosion resistance

Heat treatment strengthening capability

Disadvantages

High temperature performance is limited

High processing cost

Aluminum 7075

7075 aluminum alloy is one of the strongest commercially available alloys.

Advantages

Tight structure Strong corrosion resistance

High tensile strength

Excellent impact resistance

Excellent fatigue resistance

Disadvantages

Expensive, high cost

Difficult to process, slow extrusion speed

Aluminum 5052

Aluminum 5052 is a non-heat treatable alloy.

Advantages

Excellent corrosion resistance

Good welding performance

Excellent processing performance Combination of medium strength and light weight

Disadvantages

Cannot be heat treated and strengthened

High processing cost

Poor high temperature performance

Low hardness

Aluminum 5005

Aluminum 5005 is a common aluminum alloy material composed of aluminum and other alloy elements.

Advantages

Good corrosion resistance

Excellent formability

Good mechanical properties

Disadvantages

Cannot be heat treated to strengthen

Poor high temperature performance

Insufficient tensile strength

Aluminum 5083

Aluminum 5083 is an Al-Mg alloy with a wide range of uses.

Advantages

Excellent corrosion resistance

Excellent welding performance

Medium strength and light weight

Good cold working performance

Disadvantages

Cannot be strengthened by heat treatment High temperature performance is poor

Cutting performance is general

Plasticity decreases after cold working

2014 Aluminum

2014 aluminum is one of the strongest heat-treatable products available.

Advantages

High strength and thermal strength

Excellent machinability

Heat treatment enhancement capability

Disadvantages

Poor corrosion resistance,

Limited welding performance,

High processing cost

Aluminum 2024-T3

2024-T3 aluminum plate is a high-strength aluminum alloy material widely used in aerospace, machinery manufacturing and other fields.

Advantages

High strength

Good heat resistance

Excellent processing performance

Disadvantages

Poor corrosion resistance

Poor welding performance

CNC Machining Surface Finishes

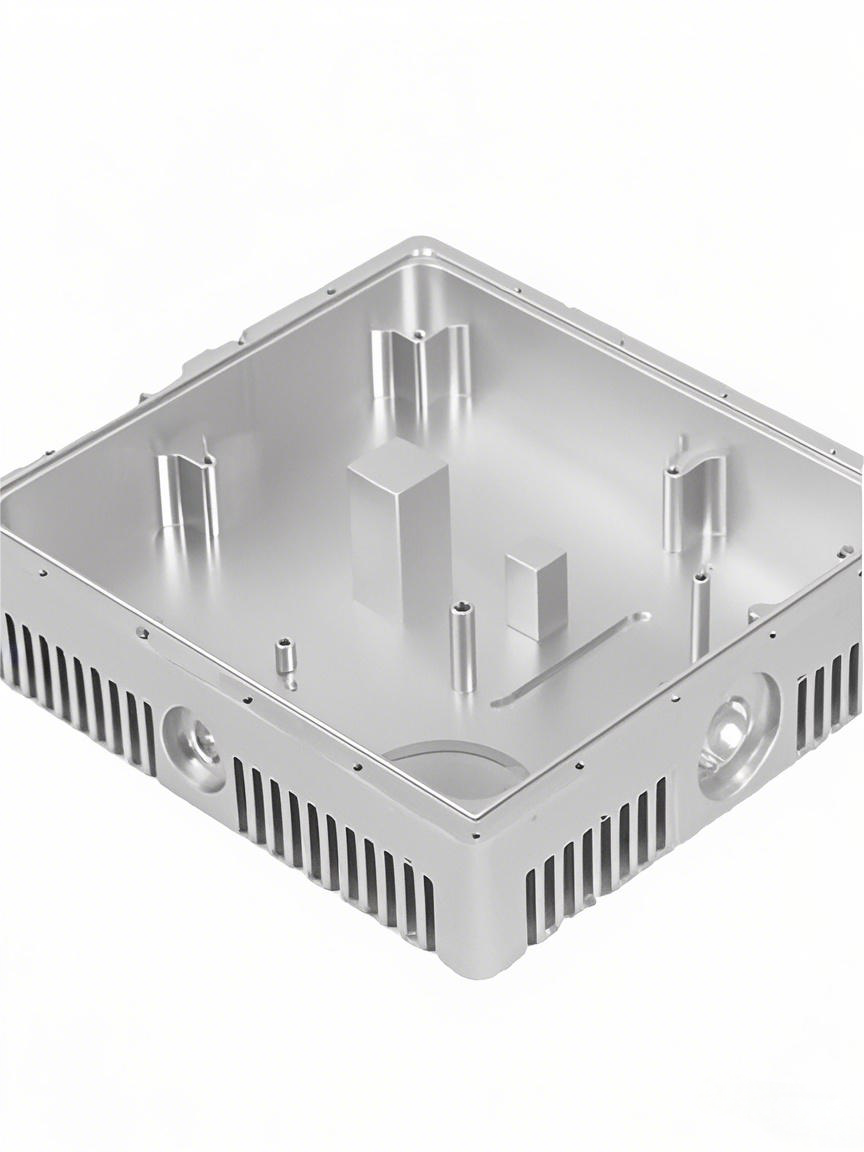

CNC machining surface treatment refers to a series of physical or chemical treatment processes on the workpiece surface after the part is cut by a CNC machine tool (Computer Numerical Control). The main purpose of these treatments is to improve the appearance, function or durability of the parts to meet design requirements and practical application needs.

As Machined1

The surface of the parts formed after processing will have clear processing lines, and usually there will be surface treatments such as deburring and sharp edge removal.

Anodizing

It is the process of forming an oxide film on the metal surface by electrolysis.

Powder coating

The powder coating is sprayed onto the aluminum surface by electrostatic adsorption and cured at high temperature to form a coating.

Black Oxidation

Refers to the process of forming a dense, uniform, microporous black oxide film on the surface of aluminum through electrolysis.

Plating

The process of depositing a layer of metal or alloy on the surface of aluminum by electrolysis to improve conductivity, wear resistance, decorative properties or corrosion resistance.

Sandblasting

It is a pretreatment performed before metal surface preparation, metal priming, painting surfaces or bonding.

Heat Treatment

An important metal processing technology that changes the internal structure of metal parts by heating and cooling, thereby significantly improving their material properties.

Polishing

Chemical or electrolytic polishing to obtain mirror effect, often used for high-gloss parts.

Brushed Finish

A surface treatment method that uses a flat-pressed abrasive belt and a non-woven roller brush to form lines on the workpiece surface to achieve a decorative effect.

Electrophoresis

The electric field is used to deposit charged paint particles on the aluminum surface to form a uniform coating.

Passivation treatment

A surface treatment technology designed to enhance the corrosion resistance of stainless steel and other specific metal materials.

Milling/Grinding

Specific textures or geometric structures are formed by CNC machining or belt sanding.

CNC Machining Tolerances And Standards

With our CNC milling and turning technologies, we can produce parts of various sizes and complexities for a wide range of applications. From single prototypes to high-volume production, we deliver consistent quality, reliable dimensions, and a flawless surface finish. Parts can be manufactured to your exacting 2D and 3D drawings, meeting ISO 9001:2015 and ISO 13485:2016 certified standards or to specific tolerances.

| Standards | CNC Milling | CNC Turning |

| Application | Flat surfaces, slots, cavities, complex contours | Round, shaft-type, symmetrical parts |

| Tolerance | ±0.01 mm | ±0.005 mm |

| Maximum Part Size | 4000 × 1500 × 600 mm | Ø300 × 500 mm |

| Minimum Wall Thickness | 0.5 mm (0.02 in), depending on material & geometry | 0.5 mm (0.02 in), depending on material & geometry |

| Surface Roughness | Ra 0.8 μm or better | Ra 0.4 μm or better |

| Quantities | From 1 prototype to 10,000+ parts | From 1 prototype to high-volume production |

| Materials | Aluminum alloys, stainless steel, copper, engineering plastics, etc | Steel, aluminum, brass, copper, stainless steel, plastics, etc. |

CNC Machining Design Guidelines

Read our practical guide to optimize production efficiency. Kaierwo experts offer immediate feedback to ensure optimal results in CNC machining.

Feature

Explaination

Part size

Machined parts are limited by the machine envelope. 3 - axis machines usually have a larger build size than multi - axis ones.5 - axis machines, though with a generally smaller build size in some cases, offer greater flexibility for complex - shape machining within their working range.

Feature alignment

For 3 - axis machining, adding features to multiple faces is costlier; aligning features on one face helps.5 - axis machining enables easier and more cost - effective machining of features on multiple faces, reducing the need for strict single - face alignment.

Fillets

Internal fillets should be large (radius > 1/3 cavity depth for 3 - axis) to use large - diameter tools and prevent damage.In 5 - axis machining, the principle holds, but access to complex geometries brings some flexibility, yet sufficient radii to avoid tool damage remain key.

Wall thickness

Metal parts need a minimum 0.8 mm wall thickness, plastic 1.5 mm (3 - axis, as thinner walls vibrate/deform).5 - axis machining may reduce vibration; minimum requirements still apply, but might allow slightly thinner walls in carefully evaluated cases.

Cavity depth

For 3 - axis, cavity depth ≤ 4x width to reduce issues.5 - axis, with shorter tools and better access, can increase depth to 6 - 8x width (depends on material, tooling, geometry).

Holes and threads

For 3 - axis, hole/thread diameters match standard tools, hole depth ≤ 10x diameter.5 - axis can improve deep - hole machining, extending the depth - to - diameter ratio to 12 - 15x in favorable situations (material/tool quality matters).

Undercuts

3 - axis: T - slot undercuts 3 - 40 mm wide; dovetail undercuts best at 45/60 degrees.5 - axis: Handles more complex undercut shapes/angles, expanding design possibilities.

Design Tips for CNC Milled Parts

CNC Machining For Various Industrial Applications

Our CNC machining service have been qualified by worldwide customers from different industries. We have been offering CNC machined parts for various industries which include the below list and more.

Automotive

Durable prototypes & production parts

Tolerance as tight as ±0.01 mm

5-axis linkage one-step machining

Support diverse material processing

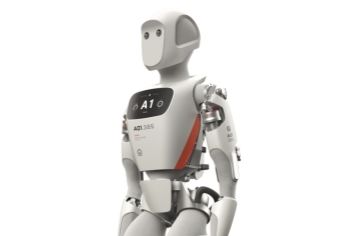

Robotics

Precision gears, housings, and actuators

Having much similar experience

No MOQ,1pcs can be produce

Fast lead time

Medical Devices

ISO 13485 compliant machining

Rapid prototyping

Tolerance as tight as ±0.01 mm

A variety of environmentally friendly materials

Why Use Our Aluminum Machining Service

Ultra-Precision Machining

•±0.005mm accuracy | Advanced 5-axis technology

•98%+ pass rate | Rigorous testing

•Dual certifications: ISO 13485 & ISO 9001

End-to-End Efficiency

•One-stop service model eliminating intermediate steps

•24/7 engineering support with 30-minute rapid quotation

•Standard production in 7 days | Priority expedited service in 3 days

More than 14 years of industry leadership

•More than 200 certified experts and technicians

•Covering industries such as automotive, medical and aerospace

•Customer repurchase rate in various industries is as high as 85%

Plastic CNC machining comes in handy when non-printable materials are needed. With this technology, we can not only make plastic concept models and precise function al components but also provide complete solutions for the production needs of low-volume machining.

Aluminum is one of the most popular machining materials thanks to its workability, strength, and versatility. What's more, its low cost makes it perfect for prototypes, end-use products, and custom tools for molding. From standard grades like 6061 to high-quality aerospace grades like 7075, we have an aluminum alloy for every CNC machining project.

01

Upload CAD Files

Firstly please upload CAD files and the main informations (material,quantity, surface treatment, etc.) All parts are supported under NDA.

02

Manufacturability Analysis And Offering Quotation

Secondly, we will analyze manufacturability based on CAD design of the parts, then provide you with a professional quotation within 12 hours.

03

Start Manufacturing

Thirdly, we will start manufacturing process once all relevant details are fully confirmed.

04

Parts are Finished and Delivered

Finally, when the parts are finished and confirmed by your side, we will carefully package and then deliver.

CNC Success Stories & Testimonials

Here are some of the CNC machining projects that we have done for our customers. And the happiness they would like to share when they receive the parts.

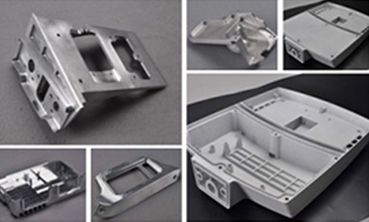

Aluminum shells machinning

Stainless steel parts

Heatsink wire cuting EDM CNC

Aluminum Shells Machinning

Aluminum Shells Machinning

CNC Machinning

Aluminum parts

Magnesium CNC Machining

Shaft CNC turining lathe

Axis CNC Machining

14years

Industry Experience

150+

Dedicated Employees

6000+

Square Meters of Factory

40000+

Projects Delivered

FAQ

1.What kind of services a CNC machining offers?

Kaierwo CNC machining process can offer a wide range of services including professional guidance on drawing design, parts processing, surface treatment, packaging and transportation, such as threading, turning, milling. drilling, prototyping tapping, part design, and reverse engineering, parts dispatching, and limited material warehousing.

2.What is the role of CNC machinists?

CNC Machinists work with heavy machinery of CNC Prototype almost durin al operations from inial setup to operation and production of differentparts and tools from plastic, metal, and other materials. The finalstep incudes drlling grinding. and cutting of the material based on the instructionsguided by CNC Machinist.

3.What is meant by the 5 axes on a CNC machine?

The term axis represents the direction of movement of the cutting tool. n a 5-axis machine, thedrlling or cutting tool rotates on Aand B while moveson X, Y and,Z linear axes and approach the work-piece in any direction.5-axis CNC machining can produce more complex and precise parts, such as aerospace landing components, medical surgical precision instruments, sensors, etc.

4.Can KAIERWO make design drawings for me?

We do not provide design services. You are required to submit 2D and 3D CAD drawings, but our professional technicians will provide technical guidance on your drawings. Drawing on our extensive experience in parts manufacturing, we can provide you with optimized recommendations for component structure and materials. Upon receiving your order, we will provide a design plan for manufacturing review.

5.How do l know my design will be kept confidential?

We of coursewil sign and adhere to any non-disclosure or confidentiality agreement. We also have a strict policy within our factory that no photographs are ever lwed of a customers product without express permission. Ultimately we rely on our reputation of working with hundreds ofthousands of unique designs over many years and never allowing any proprietary information to be disclosed to a third party.

We attach great importance to customers' needs for product quality and rapid production.

We always insist that meeting customers' needs is to realize our value!