-

+86 133 9281 9446

+86 133 9281 9446

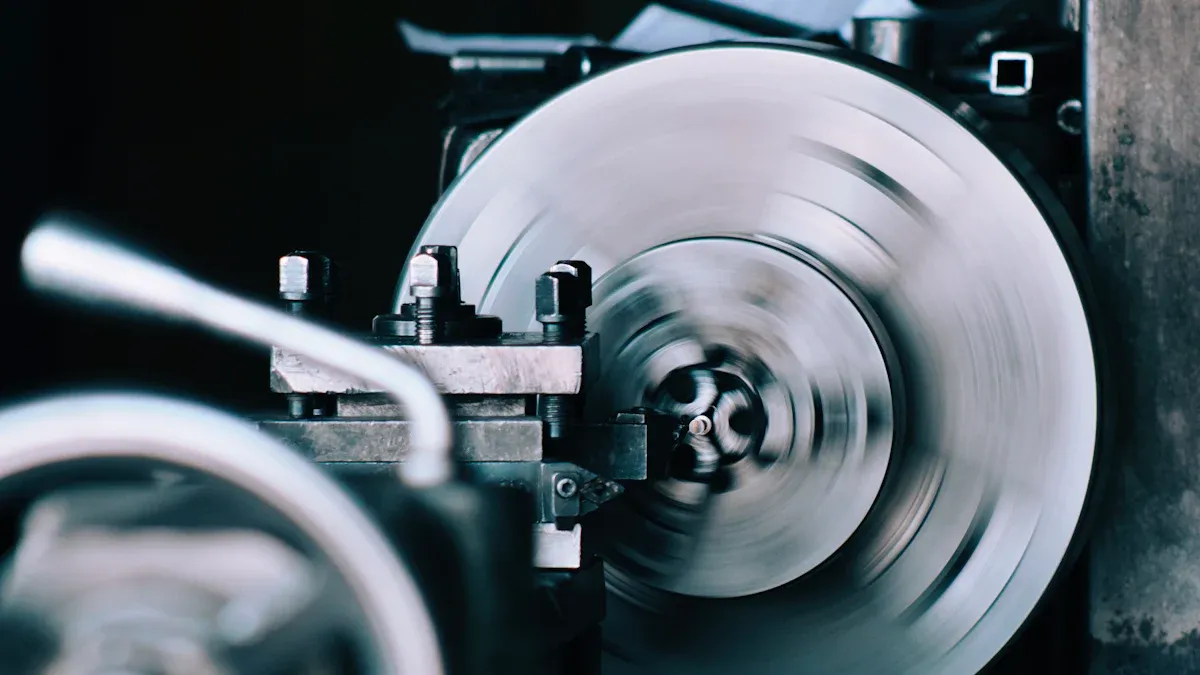

When you begin a CNC project, picking CNC machining materials is important. The materials you choose help decide if your parts will work well. CNC machining materials can be many types of metals and plastics. Each material has its own strength, hardness, and toughness. For example, steel is good for parts that hold heavy loads. Aluminum is better for parts that need to be light. The table below shows how different CNC machining materials change how parts perform:

Material | Strength | Hardness | Toughness | Ideal Use Case |

|---|---|---|---|---|

Steel | High | High | High | Load-bearing components |

Titanium | High | Medium | High | Aerospace applications |

Aluminum | Medium | Low | Medium | Lightweight brackets |

ABS | Low | Low | Low | Prototypes or simple parts |

PEEK | High | High | Medium | High-stakes applications |

Picking the right CNC machining materials means you match the material’s features to your project. You need to think about things like strength, cost, and how easy it is to machine. For example, aluminum and brass are easy to machine fast. Titanium and stainless steel take more time and care. Weather, like wetness or heat, also matters when you choose. With the best CNC machining materials, you can make strong and useful parts for any job.

Picking the right cnc machining materials is very important. It helps you make strong and safe parts. You need to think about many things before you start.

When you choose cnc machining materials, look at some main things. Each thing changes how your parts work in real life. Here is a table with the most important things to check:

Factor | Description |

|---|---|

Temperature Resistance | Materials must handle high heat and stay strong. For example, PVC gets weak at 280°F. |

Weight and Stress Capacities | Heavy materials are good for tough jobs. Light materials are better when weight matters. |

Durability Factors | Check tensile strength, endurance, wear resistance, and hardness. This helps your parts last longer. |

Material Compatibility | Metals like steel, brass, and aluminum, and plastics like PP, POM, and PC, are used a lot. |

Environmental Considerations | Think about how materials react to wetness, heat, and other things. |

Cost Analysis | Try to balance cost with the features you need. |

You also need to see how easy it is to machine each material. Here are some tips:

Steels with lots of carbon are hard to machine. Low-carbon steels can stick to tools.

Stainless steel is hard and sticky. Sometimes, making it a little harder helps.

Aluminum is easy to machine. Softer types can make rough surfaces. Use good cutting tools for best results.

Thermoplastics are tricky because they do not move heat away well. This can wear out your tools.

Composites are the hardest to machine. They do not move heat and can be rough on tools.

You should also check certifications and standards. Many jobs need cnc machining materials that follow strict rules. Some common standards are:

ISO 9001: This makes sure products are always good quality.

AS9100: This is for aerospace and means the material is very safe.

RoHS Compliance: This makes sure materials do not have bad chemicals. This is important for electronics.

You can ask for Material Test Reports (MTRs) to check what is inside your materials. These reports help you know your parts will work well.

Thinking about the environment is important too. Many companies use recycled metals or plastics that break down. Aluminum and steel alloys are easy to recycle and stay strong. You can also recycle brass, copper, titanium, and other metals. Recycling saves energy and helps the earth.

Tip: If you want to help the planet, pick materials from nearby and recycle scraps. This saves energy and money.

Every project needs something different. You must match your cnc machining materials to your job. Here are some things to think about:

End-use of the part: Know how and where your parts will be used. Aerospace parts need to be light and strong. Automotive parts need to handle heat and stress.

Weight requirements: If you need light parts, pick aluminum or some plastics.

Strength and heat resistance: Some jobs need materials that handle stress or heat. Titanium and stainless steel are good for these.

Budget constraints: Think about cost. Some materials cost more, but you may need them for special jobs.

Here are some examples of how different industries pick materials:

Aerospace: Uses titanium and aluminum for light and strong parts.

Automotive: Picks steel and plastics for parts that handle heat and stress.

Electronics: Needs RoHS-compliant plastics and metals for safe parts.

Medical: Picks materials that meet ISO 13485 for safety and cleanliness.

Note: Always check the certifications and test reports for your cnc machining materials. This helps you avoid problems and makes sure your parts are right.

By thinking about key things and project needs, you can pick the right material for your cnc machining. This helps you make strong, safe, and low-cost parts for all your jobs.

When you begin a cnc project, you should learn about common materials. These materials help you make parts that are strong, light, or special. You can choose metals or plastics. Each group has its own good points and uses.

Metals are very popular for cnc machining. You use metals when you need parts that are strong or tough. Metals also work well if you need heat-resistant parts. Here is a table that shows the main properties of common metals for cnc:

Metal | Key Properties | Machining Difficulty | Cost | Typical Applications |

|---|---|---|---|---|

Aluminum | Lightweight, corrosion resistance, high machinability, good thermal and electrical conductivity | Easy | Low | Aerospace, automotive, electronics |

Steel | High strength, durable, versatile, heat treatable | Medium | Medium | Machinery, tools, automotive |

Stainless Steel | Superior corrosion resistance, high strength, hygienic, shiny surface | Hard | High | Medical, food, marine, architecture |

Brass | Good strength, flexible, corrosion resistant, antimicrobial | Easy | Medium | Valves, fittings, musical instruments |

Copper | High electrical and thermal conductivity, antimicrobial | Medium | High | Electrical, plumbing, heat exchangers |

Titanium | Strong, light, corrosion resistant, biocompatible, handles high heat | Hard | Very High | Aerospace, medical, racing |

Each metal has its own strong points. Aluminum is light and easy to cut. Steel is strong and good for hard jobs. Stainless steel does not rust and looks shiny. Brass is easy to shape and does not corrode. Copper moves heat and electricity well. Titanium is strong and light, but it costs more and is harder to cut.

Tip: If you want parts made fast and cheap, pick aluminum or brass. If you need parts that last in tough places, use stainless steel or titanium.

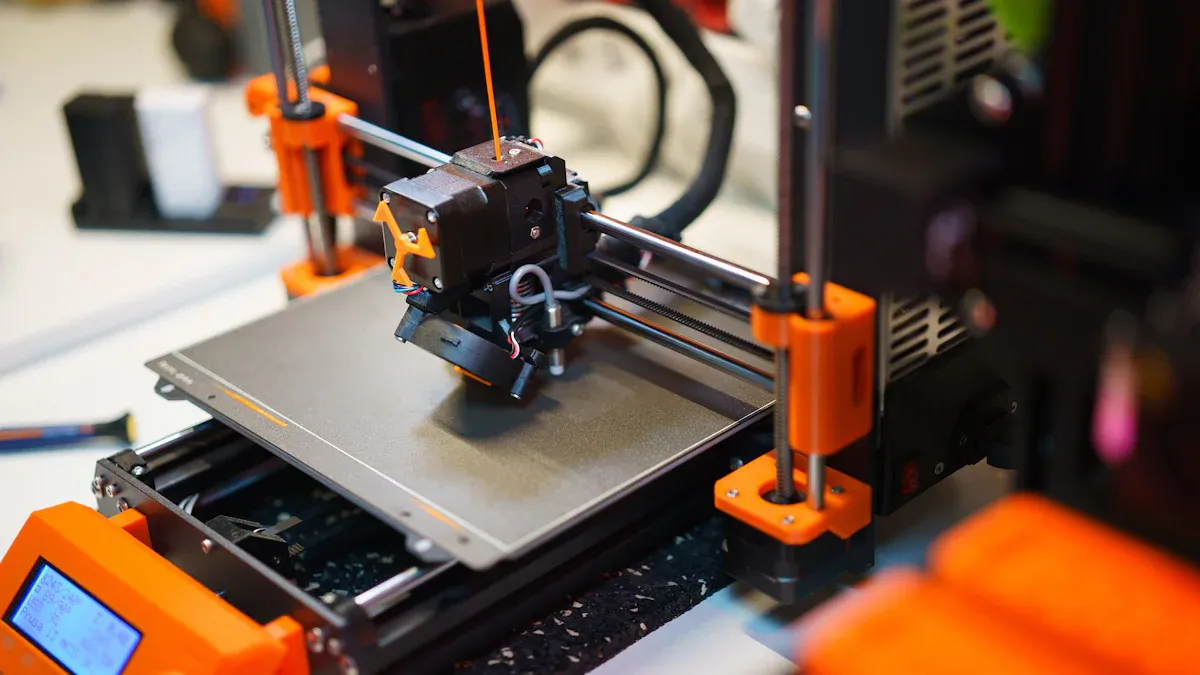

Plastics are also used a lot for cnc. You use plastics when you need parts that are light or flexible. Some plastics can even take the place of metals in some jobs. Here is a table that shows the main properties and uses of popular plastics for cnc:

Plastic Type | Key Properties | Machining Difficulty | Cost | Typical Applications |

|---|---|---|---|---|

ABS | Tough, impact resistant, easy to machine | Easy | Low | Prototypes, toys, housings |

Nylon (PA) | High strength, self-lubricating, flexible | Medium | Medium | Gears, bearings, bushings |

PEEK | High chemical resistance, light, biocompatible | Hard | Very High | Medical, aerospace, high-tech parts |

Polycarbonate | Strong, clear, impact resistant | Medium | Medium | Shields, lenses, safety equipment |

POM (Delrin) | High strength, stable, low friction | Easy | Medium | Gears, valves, precision parts |

ABS works well for test parts and covers. Nylon is good for moving parts like gears. PEEK is very strong and safe for the body, so it is used in medical and aerospace jobs. Polycarbonate is clear and tough, so it is used for windows and shields. POM is smooth and strong, perfect for gears and small moving parts.

Note: Some plastics, like PEEK, cost more and are harder to cut. You should pick them only if your job needs their special features.

When you pick candidate materials for cnc, think about what your part needs to do. Metals give you strength and heat resistance. Plastics give you light weight and special features.

Aluminum is picked a lot for cnc jobs. It is light and strong. You can cut aluminum easily. It has a good strength-to-weight ratio. Aluminum works well for parts that need to fight rust. It also does well in cold places. You can recycle aluminum easily. You can add a layer to protect it more. Here is a table with common aluminum alloys and what they are used for:

Alloy | Mechanical Properties | Typical Applications |

|---|---|---|

6082 | Fights rust, strong | Trusses, bridges, cranes, transport |

7075 | Best strength-to-weight ratio | Gears, shafts, valves, missile parts |

2024 | Handles lots of stress | Aircraft, automotive components |

5052 | Good at fighting rust | Pressure vessels, kitchen appliances |

5080 | Fine grain structure | PCB substrate, gages, molds |

MIC-6 | Stress-relieved, fast machining | Tooling applications |

Tip: Aluminum is fast and easy to machine. It needs less power than steel. It keeps its shape well.

Stainless steel is chosen for cnc when you need tough parts. It does not rust because it has chromium. Stainless steel is light and strong. You can clean it easily. It is used in medical tools, food machines, and boat parts. Stainless steel is good for making exact parts.

Stainless steel does not rust or get dirty.

You can clean it without trouble.

It meets safety rules.

You get strong and lasting parts.

Tip: Use sharp tools and go slow with stainless steel. This stops tool damage and makes smooth parts.

Brass is a smart pick for cnc if you want easy cutting. Brass looks nice too. It is made from copper and zinc. Brass fights rust well. You can shape brass easily because it is soft. It melts at a low temperature. Brass is used for valves, fittings, and pretty parts.

Brass does not rust, even in salty water.

You get smooth and detailed shapes.

Brass can wear out tools faster than aluminum. Check your tools often.

Tip: Brass is good for parts that need to work and look nice. It is great for musical instruments and plumbing.

Copper is used for cnc when you need to move electricity or heat. You see copper in power, cars, and planes. Copper fights rust and kills germs. Here is a table with copper alloys and their features:

Copper Alloy | Electrical Conductivity (IACS) | Thermal Conductivity (W/(m⋅°C)) |

|---|---|---|

C101 | 96.5% | 390 - 398 |

C110 | 101.5% | 380 - 388 |

Copper is almost as good as silver for moving electricity and heat.

You use copper for wires, heat exchangers, and medical tools.

Tip: Be careful when you cut copper. It is soft and can stick to tools. Use sharp cutters and keep your area clean.

Titanium is picked for cnc when you need strong parts. It handles stress and heat well. You see titanium in planes and medical jobs. Titanium is strong but light. It fights rust and stands up to high heat. Cutting titanium is hard. You need special tools and must go slow. Here is a table with good points and hard parts:

Benefits | Challenges |

|---|---|

Strong but light | Reacts with chemicals |

Fights rust | Does not move heat well |

Handles high heat | Wears out tools when cutting |

Titanium is tough and does not move heat well.

Chips can stick to tools, so watch for tool damage.

Tip: Use coolant and sharp tools for titanium. This helps you make good parts and keeps your tools safe.

ABS is good for cnc if you want strong parts. It does not break easily when hit. You can cut and shape ABS without trouble. This plastic is used for test parts, covers, and cases. It keeps out chemicals and electricity. ABS does not cost much and works for many jobs.

Property | Description |

|---|---|

Impact Resistance | Tough and stiff, does not break easily |

Machinability | Easy to cut, good for making exact shapes |

Very tough

Handles bumps well

Easy to machine

Tip: Try ABS for test parts or covers that might get dropped.

Nylon is a good pick for cnc if you need parts that bend. It is strong and does not wear out fast. Nylon can bend and stretch without snapping. People use nylon for gears, bushings, and moving parts.

Feature | Description |

|---|---|

Flexibility | Bends and stretches without breaking |

Wear Resistance | Lasts long, even when parts move a lot |

Low Friction | Slides easily, does not need oil |

High Strength | Stronger than many other plastics |

Tip: Nylon is great for gears or bushings that move a lot.

PEEK is a special plastic for cnc. Use it when you need parts that face heat or chemicals. PEEK stays strong even when it gets hot. It does not soak up much water. PEEK is used in medical, airplane, and electronic parts.

Property | Description |

|---|---|

High-temperature performance | Stays strong above 482°F |

Chemical resistance | Does not get damaged by many chemicals |

Moisture absorption | Takes in very little water |

Wear resistance | Does not wear out fast |

PEEK is good for tough jobs.

It makes safe and lasting parts.

Tip: Cut PEEK slowly and use sharp tools so it does not melt.

Polycarbonate is a clear and strong plastic for cnc. You can see through it easily. It does not break when hit. Polycarbonate stays tough in hot or cold places. People use it for shields, lenses, and safety gear.

Property | Description |

|---|---|

Refractive Index | 1.548, very clear |

Transparency | Stays see-through, even with color |

Impact Resistance | Very tough, does not break when hit |

Temperature Range | Stays strong from -20°C to 140°C |

Tip: Pick polycarbonate for windows or covers that must be clear and strong.

POM, or Delrin, is great for cnc if you need exact and steady parts. It is easy to cut and gives smooth finishes. POM does not soak up much water, so parts keep their size. You use POM for gears, valves, and small moving parts.

Property | POM | ABS |

|---|---|---|

Dimensional Stability | Keeps size, does not take in water | Changes size, takes in more water |

Machinability | Easy to cut, very exact shapes | Good, but not as exact |

Surface Finish | Smooth finish, looks nice | Needs more work to look smooth |

Tip: Use POM for small parts that must fit well and last long.

You have many plastics to pick for cnc. Each one has special features for your project.

When you pick cnc materials, you must look at metals and plastics. These two groups are different in many ways. They have different strengths, prices, and uses. If you know these differences, you can choose the best material for your cnc parts.

Metals and plastics act in different ways during cnc machining. Metals are strong and last a long time. Plastics are lighter and do not rust. You can see how they compare in this table:

Material | Advantages | Disadvantages |

|---|---|---|

Plastics | Faster machining speeds, Less tool wear, Light weight, Good corrosion resistance, Good insulating properties | Low strength and hardness, High thermal expansion, Surface quality issues, Poor temperature resistance |

Metals | High strength and hardness, Good dimensional stability, Excellent surface quality, Good high temperature resistance, Diverse mechanical properties | Difficult to machine, Fast tool wear, High material costs, High weight, Poor corrosion resistance |

Plastics are good for parts that do not hold heavy loads. Metals are better for parts that must be strong or handle stress. Plastics do not rust on their own. Some metals, like stainless steel and titanium, can resist rust after special treatment.

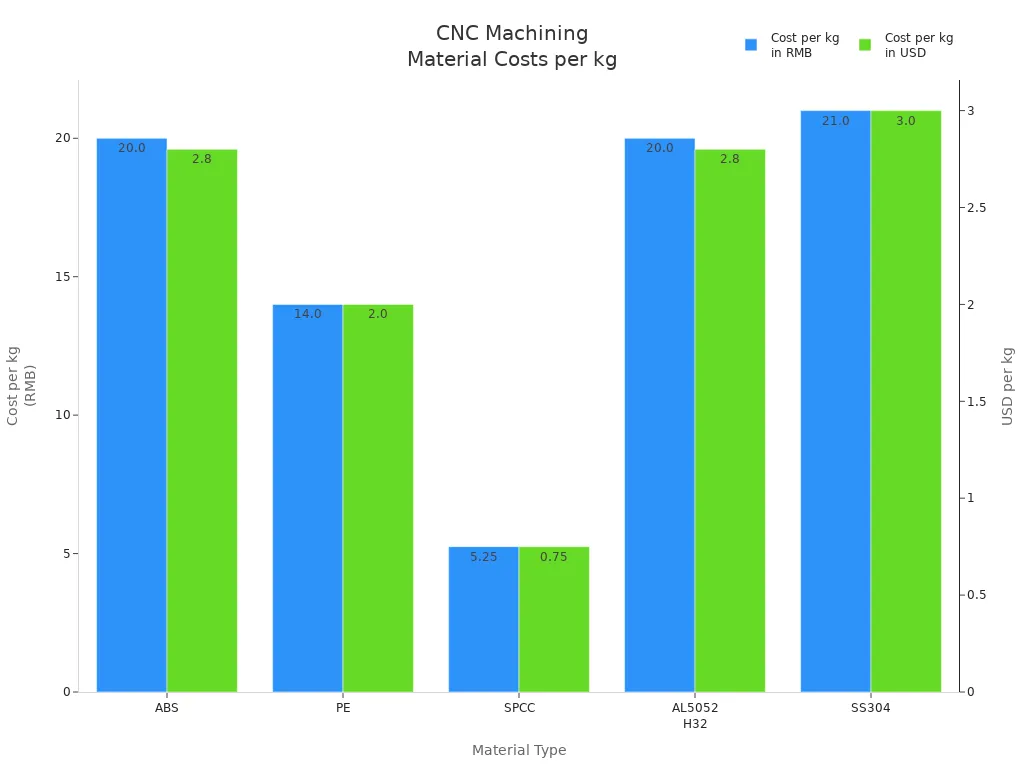

Cost is very important in cnc machining. Plastics usually cost less than metals. Plastics are also faster to machine, so you save money. Metals like stainless steel and titanium cost more and take longer to cut. The chart below shows the average price per kilogram for common cnc materials:

Plastic and aluminum are cheaper to machine. Stainless steel, brass, and titanium cost more because they are harder to cut. The material you pick changes how much your project will cost.

Metals and plastics are used for different cnc jobs. Metals are strong and work well for frames or parts that get a lot of stress. Plastics are light and good for covers or cases. Here are some common uses:

Material Type | Typical Applications |

|---|---|

Metals | Aerospace frames, automotive parts, connectors, heat sinks, machinery |

Plastics | Housings, enclosures, gears, bushings, medical devices, electronics covers |

Metals are best for parts that need to be strong and last a long time. Plastics are great for parts that need to be light, stop shocks, or keep out electricity.

When picking CNC machining materials, you must think about a few key things. The table below shows what is most important:

Consideration | Description |

|---|---|

Machinability | Easy-to-machine materials help you save time and money. |

Material Costs | Choosing the right cost and quality keeps you on budget. |

Availability | Materials that are easy to find help your project move fast. |

Part Application | Make sure the material fits how you will use the part. |

Operating Environment | Pick materials that can handle heat, chemicals, or stress. |

Aluminum and ABS are good for prototypes. These materials are simple to cut. They do not cost a lot. You can make parts quickly. This helps you test your ideas fast.

Think about what your part must do. Metals are strong and handle heat well. Plastics are light and bend easily. Pick the material that fits your needs best.

You can recycle many metals like aluminum and steel. Some plastics can be recycled too. Recycling saves money and helps the planet stay clean.

Look for ISO 9001 for good quality. ISO 13485 is for medical parts. RoHS is for safe electronics. These certifications help you trust your materials.

Contact Us

Rapid Prototyping CNC LIST

Die Casting Service Supplier|KaierwoCNC Machining Process OverviewHow to Reduce Time-to-Market for Medical Devices with Rapid Prototyping5 Axis Machining Services|KaierwoAluminum CNC Machining: High-Precision Aluminum CNC ServicesThe Role of 3D Printing in Personalized Healthcare SolutionsCommon Vacuum Casting Industry TermsRapid Prototyping Industry Glossary: Key Manufacturing Terms ExplainedFrom Design to Delivery: How Low Volume Manufacturing Accelerates CustomizationComprehensive Guide to 3D Printing Surface Finishing MethodsPlastic Injection Mold Making and Custom Casting MoldsAluminum surface finishing for corrosion resistanceAdvantages of CNC TurningCNC Machining for Rapid Prototyping Design TechniquesSheet Metal Fabrication Services|KaierwoRapid Tooling Service CompanyCNC machining materials3D Printing Industry GlossaryPrecision Aluminum Machining ServicesTop 10 Factors to Consider When Selecting a Plastic Injection Molding Service ProviderApplications of Vacuum Casting3D Printing Service FAQsThe Advantages of 3D Printing ServicesWhat is Casting? Understanding the Fundamental Metal Forming Process3D Printing Die Casting: Revolutionizing Manufacturing ProcessesHow to Reduce Lead Time in Rapid Prototyping Additive Manufacturing ProjectsA Complete Guide to CNC Machining50 Must-Know CNC Machining TermsSLM Metal 3D Printing Service3D Printing Complete GuidePlastic Prototyping Methods: Processes, Materials, Tolerances, and DFM TipsOne-Stop Aluminum CNC Machining: From Rapid Prototype to Small-Batch Electronics EnclosuresHow to ensure your rapid prototype meets the final product specificationsVacuum Casting Materials GuideCNC Machining Aluminum and Plastic ServicesAluminum CNC Machining Quotation GuideCNC Milling Service CompanyPrototype Manufacturing Technologies & Tools: A Complete GuideAluminum Processing Industry GlossaryCNC Machining Services | Kaierwo Precision ManufacturingRapid Prototype ToolingCheap CNC Milling ServicesHow to Validate a Medical Prototype Before Production?Frequently Asked Questions about CNC MachiningComplete Guide to 3D Printing Materials