We attach great importance to customers' needs for product quality and rapid production.

We always insist that meeting customers' needs is to realize our value!

+86 133 9281 9446

Oct. 22, 2025

Leo Lin.

I graduated from Jiangxi University of Science and Technology, majoring in Mechanical Manufacturing Automation.

You often ask, "How much does 3d printing cost?" The answer depends on your chosen technology, project scope, and whether you use a professional service or print at home. For example, the average 3d printing cost for materials varies:

Technology | Material | Average Cost(per kg) |

|---|---|---|

FDM | PLA | $20 - $40 |

ABS | $25 - $50 | |

SLA/DLP | Standard Resin | $50 - $100 |

SLS | Nylon | $50 - $80 |

SLM | Stainless Steel | $300 - $800 |

You need to consider several factors that influence 3d printing cost:

Equipment

Materials

Software

Maintenance

Indirect expenses

Understanding each 3d printing cost component helps you make informed choices. Whether you use a DIY setup or a service like Kaierwo, you can optimize 3d printing cost for your needs.

Understanding the main factors that influence 3D printing cost helps you make informed decisions for your projects. Each element, from equipment to software, plays a unique role in shaping your total expenses.

The type of 3d printer you choose has a significant impact on your initial investment and ongoing costs. You can select from a wide range of machines, from affordable hobbyist printers to advanced industrial systems.

Entry-level 3d printers provide an accessible starting point for individuals and small businesses. These machines typically support basic 3d printing materials and offer straightforward operation. You can expect to pay between $280 and $3,999 for a reliable entry-level model. These printers are ideal for prototyping, educational use, and small production runs.

Type of 3D Printer | Price Range |

|---|---|

Entry-Level | $280 - $3,999 |

Hobbyist printers often use FDM technology, which keeps material costs low and maintenance simple. You benefit from a lower upfront cost, but you may face limitations in print size, speed, and material compatibility.

Industrial 3d printers deliver higher performance, larger build volumes, and support for advanced materials. These machines suit businesses that require precision, durability, and scalability. Prices for industrial systems range from $4,299 to $19,999, with some specialized models costing much more.

Type of 3D Printer | Price Range |

|---|---|

Industrial | $4,299 - $19,999 |

Industrial printers often use technologies such as SLA, SLS, and SLM. Each technology brings unique cost implications:

Technology | Material Costs | Operational Costs | Notes |

|---|---|---|---|

FDM | Low | Moderate | Best for simple parts and small runs |

SLA | High | Low | Excellent surface quality, fast setup |

SLS | High | Moderate | No support structures needed, reusable powder |

SLM | Very High | High | Ideal for strong metal parts |

The choice of 3d printing materials directly affects both cost and quality. Material prices vary widely depending on type and technology. For example, FDM filaments like PLA and ABS remain affordable, while specialty resins and powders for SLA or SLS can be much more expensive.

Material | Printing Technology | Average Cost Per 1kg |

|---|---|---|

PLA | FDM | $15 – $40 |

ABS | FDM | $20 – $50 |

PETG | FDM | $20 – $60 |

TPU | FDM | $40 – $100 |

Standard Resin | SLA | $20 – $50 |

Engineering Resin | SLA | $70 – $200 |

PA 12 Nylon | SLS | $150 – $250 |

You should also consider material waste, especially with complex designs that require supports or have a higher risk of print failure. Larger parts and intricate geometries increase material usage and, therefore, total cost.

Different materials provide unique mechanical and thermal properties, which influence the final product's performance.

Complex designs may require more material and time, raising costs.

Post-processing, such as support removal and finishing, adds to your expenses.

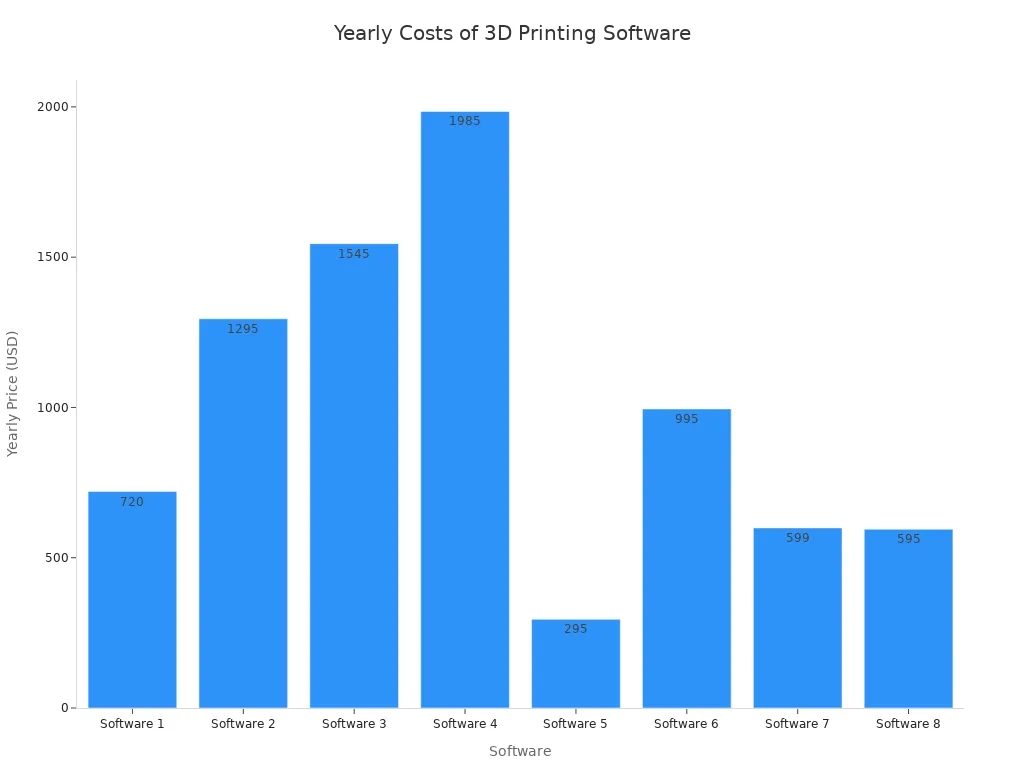

Software is another essential factor in your 3D printing budget. You need design and slicing software to prepare your models for printing. Costs range from free basic programs to advanced professional suites with annual fees or perpetual licenses.

Software Type | Price (Yearly) | Perpetual License | Solid Modeling | Intended Users |

|---|---|---|---|---|

Software 1 | $720 | $3,945 | No | Amateurs to professionals |

Software 2 | $1,295 | $3,995 | Yes | Amateurs to professionals |

Software 3 | $1,545 | N/A | No | Advanced users and professionals |

Software 4 | $1,985 | N/A | Yes | Advanced users and professionals |

Software 5 | $295 | N/A | Yes | Amateurs to advanced users |

Software 6 | $995 | N/A | No | Advanced users and professionals |

Software 7 | $599 | $1,799 | No | Amateurs to professionals |

Software 8 | Free (personal) / $595 (commercial) | N/A | Yes | Amateurs to professionals |

Advanced software often supports complex geometries, dual extrusion, and specialized materials. These features help you achieve higher-quality prints but may require a greater investment. Free options work well for basic projects, but professional users often benefit from paid solutions that offer robust modeling and compatibility with a wider range of 3d printer technologies.

Note: The right software can streamline your workflow, reduce errors, and help you get the most out of your equipment and materials.

Labor plays a critical role in determining your overall 3D printing cost. You must account for the time and expertise required to prepare models, operate printers, and finish parts. The complexity of your project directly influences labor expenses. When you design intricate parts with overhangs or require support structures, you increase print time and post-processing needs. These factors drive up labor costs and extend production schedules.

You can manage labor costs more effectively by optimizing your designs. Simple geometries and minimal supports reduce the time needed for setup and finishing. Skilled technicians can help you streamline workflows and avoid unnecessary steps. If you choose advanced technologies like SLA, SLS, or SLM, you may need specialized operators who understand the nuances of each process. Their expertise ensures high-quality results but may add to your labor budget.

Consider the following factors that impact labor costs in 3D printing:

Intricate designs and complex geometries require more time for setup, monitoring, and post-processing.

Overhangs and support structures increase manual labor during print preparation and removal.

Skilled workers can optimize part orientation and material usage, reducing waste and improving efficiency.

3D printing projects often need fewer workers than traditional manufacturing. You may only need three to four skilled technicians, compared to ten to twelve people for conventional methods. This shift can result in up to 40% labor cost savings.

Tip: You can reduce labor expenses by simplifying your designs and leveraging the expertise of experienced technicians. Choose the right technology for your project to balance quality and cost.

Kaierwo stands out by offering a full-cycle, one-stop 3D printing solution. You benefit from fast turnaround, with quick quotes available in as little as three hours and projects dispatched in five days or less. This speed helps you reduce project costs and accelerate your time to market.

Kaierwo’s service can reduce your costs by up to 30%.

A Southeast Asian energy company saved 62.5% on mold costs, cutting expenses from $12,000 to $4,500.

Production time for molds dropped from 45 days to just 12 days, a 73% reduction.

Material utilization improved from 65% to 88%, saving thousands in material costs.

Customers have achieved a 22% reduction in unit cost and completed delivery 15 days ahead of schedule.

"Kaierwo not only saved us 25% on prototype costs, but also enabled us to obtain clinical data three months earlier than our competitors, allowing us to successfully capture the regional market."

You also gain access to a wide range of post-processing options, such as polishing, painting, and plating. This flexibility ensures your parts meet both functional and aesthetic requirements.

When you calculate the total cost of 3D printing, you must look beyond equipment and materials. Indirect costs—such as energy consumption, time investment, and post-processing—can significantly impact your budget and project timeline.

Time is a critical but often underestimated factor in 3D printing. You invest hours not only in the actual printing but also in setup, design, and post-processing. The total time required for a project varies based on object size, complexity, and your experience level.

The entire process—from design to finished part—can take anywhere from half a day to several days.

Here is a quick overview of typical time requirements for different print sizes:

Small Object: Keychain or badge (30 minutes to 1 hour)

Medium Object: Toy figure or phone stand (2 to 5 hours)

Large or Detailed Object: Helmet, model house, or articulated dragon (10 to 24+ hours)

Post-processing also adds to your timeline. For example, SLA and DLP prints often require 1 to 2 hours of finishing, while SLS parts may need 2 to 4 hours. You should plan for these steps when estimating delivery schedules.

Post-processing enhances the appearance and performance of your printed parts. Common techniques include polishing, painting, and plating. These steps can add both time and cost to your project. For example, a basic paint correction may cost between $500 and $800, while more advanced finishing can exceed $1,000. Wet painting and powder coating offer cost-effective options, especially for larger batches.

If you use Kaierwo’s 3D Printing Service, you gain access to a full suite of post-processing options, including polishing, painting, and plating. This service streamlines your workflow and ensures professional results without the need for extra equipment or specialized skills.

Tip: Always factor in post-processing when budgeting for your 3D printing projects. Professional finishing can elevate your parts and save you valuable time.

By understanding and managing these indirect costs, you can make smarter decisions and achieve better value from your 3d printer or service provider.

Project budgeting involves more than just calculating the cost of a single print. You must consider the entire production cycle, including design, prototyping, and finishing. Start by estimating the number of parts you need and the complexity of each design. Multiply your per-print cost by the total quantity. Add expenses for software, labor, maintenance, and post-processing.

You can streamline your budgeting process by using online calculators. Many tools allow you to input parameters such as material type, print time, and energy consumption. Here are some popular options:

Top 10 3D Printing Cost Calculators: Compare features and accuracy across multiple platforms.

Unionfab Quoting Page: Focuses on industrial-scale projects and cost efficiency.

Fabbaloo: Considers both resin and filament printers for comprehensive estimates.

3D Print HQ Calculator: Lets you input detailed parameters for precise analysis.

3DWithUs: Offers a simple interface for quick material and labor cost estimates.

Shatter Box: Accounts for various financial aspects of your printing projects.

MakerShop: Analyzes STL models and includes maintenance costs.

3dpcalc: Focuses on actual material consumption and cost estimation.

You can also consult with professional service providers like Kaierwo. Their team can review your project requirements and provide a tailored quote. This approach ensures you receive an accurate estimate that covers all aspects of production, including advanced technologies and post-processing.

You can significantly reduce your 3D printing costs by focusing on material savings. Waste often comes from failed prints, excessive support structures, and inefficient designs. Start by optimizing your print parameters. Adjust infill density and print speed to use only the material you need. Lower infill percentages can still provide strength while saving filament or resin.

Choose sustainable materials like PLA, which is compostable under certain conditions.

Use recycled filaments or bio-based polymers to minimize your environmental impact.

Implement recycling practices for failed prints and leftover materials.

You should also plan your designs to minimize waste. Combine components where possible and orient parts to reduce the need for supports. Post-processing techniques such as polishing and sanding can enhance your parts without adding extra material. By promoting sustainable practices and collaborating with suppliers and recycling facilities, you help create a more efficient and eco-friendly workflow.

Selecting the most cost-effective 3D printing technology for your needs is crucial. FDM printers offer affordability and work well for basic prototypes and functional plastic parts. SLA provides high-resolution prints with smooth finishes, making it ideal for detailed models. SLS and SLM excel in producing robust, high-performance parts, especially when you need advanced materials or metal components.

The right choice depends on your project’s size, complexity, and material requirements. For large-scale or onsite projects, onsite 3D printing can reduce transportation and warehousing costs, making it more efficient. Offsite printing may suit smaller runs or when you need specialized post-processing.

By applying these strategies—minimizing material waste, maintaining your equipment, and choosing the right technology—you can control your 3D printing costs and maximize the value of every project.

You can expect a single 3D print to cost anywhere from $5 to $500. The price depends on material, size, complexity, and technology. Using a service like Kaierwo provides a clear quote before production.

You should consider your part’s function, required strength, and surface finish. FDM works well for basic prototypes. SLA offers high detail. SLS and SLM suit advanced or industrial needs. Consult with experts for the best fit.

Yes! You can lower costs by minimizing supports, reducing infill, and combining parts. Simple shapes print faster and use less material. Efficient design leads to savings in both time and money.

Watch for energy consumption, post-processing, failed prints, and maintenance. These indirect costs can add up quickly. Always include them in your project budget.

If you print often and need full control, buying may suit you. For occasional, complex, or large projects, a service like Kaierwo offers flexibility, advanced technology, and lower upfront costs.

You can receive prototypes from Kaierwo in as little as 24 to 48 hours. Complex or large orders may take longer. Fast turnaround helps you meet tight deadlines.

You can choose from polishing, painting, and plating. These options improve appearance and performance. Kaierwo includes professional post-processing to ensure your parts meet your requirements.

We attach great importance to customers' needs for product quality and rapid production.

We always insist that meeting customers' needs is to realize our value!