-

+86 133 9281 9446

+86 133 9281 9446

Rapid prototyping is a smart way to make products faster in the medical manufacturing industry. It helps medical companies get products to market sooner. You can use rapid prototyping to test designs quickly, allowing for early feedback. This method also simplifies compliance with regulations. About 27% of medical device companies now finish projects faster with this approach. Kaierwo employs special techniques like vacuum casting, which facilitates the rapid creation of prototypes and small batches of medical parts efficiently.

Industry | CAGR (%) |

|---|---|

Healthcare | 26.7 |

Manufacturing & Construction | 31.9 |

Aerospace & Defense | 25.5 |

Rapid prototyping can change how you make products in medical manufacturing. It lets you turn digital designs into real models very fast. You begin with a 3D model made in CAD software. This helps you get very exact and accurate results. Rapid prototyping uses many advanced tools to help with medical device prototyping.

Here are the main technologies used in medical manufacturing:

3D Printing: This builds objects one layer at a time. It helps you make detailed and complex prototypes quickly.

CNC Machining: Computer-controlled machines cut away material. This makes strong and very accurate prototypes.

Injection Molding: This makes many plastic parts that are all the same. It is good for testing and making medium amounts.

Laser Cutting: This cuts materials into exact shapes. It works well for flat parts.

Vacuum Casting: This uses resin in a vacuum to make high-quality prototypes. The parts look a lot like the final products.

Each tool has its own benefits. For example, 3D printing is flexible and lets you make changes fast. CNC machining gives you strong and very exact parts. Injection molding saves money when you need more parts and keeps quality the same.

Tip: Using rapid prototyping in medical manufacturing helps you check form and fit early. This makes development faster and more accurate.

Rapid prototyping can be used in many ways in medical manufacturing. It is important for making things like surgical tools, diagnostic machines, and implantable devices. With rapid prototyping, you can test designs and change them before making a lot. This helps you find problems early and make your products work better.

Medical device companies have some problems like high material costs, expensive equipment, and needing skilled workers. You can solve these problems by working together in teams and getting help from experts in additive manufacturing. Working with contract manufacturers early and thinking about how to make things easier also helps lower costs and save time.

Challenge | Description |

|---|---|

Cost and Availability of Materials | Not many material choices can change how the final product works. |

Cost of Equipment | Special machines cost a lot and can use up budgets, especially if you need to make many versions. |

Lack of Skills and Well-Trained Staff | It is hard to find workers who know a lot about rapid prototyping. |

Accuracy and Quality of Prototypes | Prototypes might not always be as exact as the final product. |

You can make your medical device prototyping better by using an iterative design process. This lets you test and improve products quickly. It also helps you meet rules and bring good medical devices to market faster.

You want your medical device to reach patients quickly. Rapid prototyping helps you do this. With 3d printing, you can make working prototypes fast. You also use less material, which saves money. This is helpful when materials cost a lot. You do not have to wait for expensive molds. You also skip long setup times. You can make small batches and try out many designs at once.

You save time because you do not need old tools.

You spend less by making only what you need.

You can test and improve your product without waiting.

Rapid prototyping helps you move from an idea to a real model in just days. This is much faster than waiting weeks. Being quick gives you an edge over others in the medical device field.

Getting feedback early is important for safe medical devices. Rapid prototyping lets you change your models quickly. You can show working prototypes to your team, doctors, and patients. This helps you find problems before they get worse.

Here are ways rapid prototyping helps with early feedback:

You can make a simple version and test it right away.

Digital tools let everyone see and talk about new designs.

You use the fastest ways to keep your project moving.

Early testing helps you find and fix safety problems.

Benefit | Explanation |

|---|---|

Improved patient outcomes | Customizing devices helps patients get better results. |

Reduced healthcare costs | Finding and fixing mistakes early saves money. |

Faster product development | Spotting problems fast helps you finish sooner. |

Increased efficiency | Better processes make healthcare work smoother. |

You can keep testing and changing your device until it is ready. This helps you make sure your design is good and gets to market faster.

Following rules is a big part of making medical devices. Rapid prototyping makes this easier. You can use working prototypes to check if your design meets FDA and other rules early. This helps you avoid problems later.

Impact Area | Description |

|---|---|

FDA Compliance | Prototyping helps you spot FDA problems before you start making lots of devices. |

International Standards | You can make different versions that follow rules in other countries. |

Design Optimization | You make sure your design follows local rules while you are still testing. |

Regulators now want to see digital records and proof during prototyping. You can use 3d printing and digital tools to track every change. This makes it easier to show you followed the rules when you ask for approval.

You work with engineers early to pick the best materials and steps.

You talk to experts to make sure your design follows all rules.

You use working prototypes to check your device before making a lot.

Rapid prototyping helps you avoid delays from rule problems. It helps you get your product to market faster. This makes the approval process smoother and helps you stay ahead.

You want to launch new medical technology fast and safely. You need a clear plan that uses rapid prototyping and follows rules. Medical device companies use five main steps to guide their work and meet standards.

Device Discovery and Concept

Start with an idea for your device. Figure out what people need. Make simple products and look for patient-specific answers.

Preclinical Research-Prototype

Build your first prototype. Test it with your team and users. Use in-house rapid prototyping or work with medical device manufacturers for good prototypes.

Pathway to Approval

Change your prototype based on feedback. Make sure your design is safe and meets quality rules.

FDA Device Review

Send your device for review. Keep records of every change and test.

FDA Post-Market Device Safety Monitoring

After approval, watch your device in the market. Collect data to make better products later.

The five-step FDA process helps guide medical device companies. It also gives access to the approval pathway.

Medical device companies do well when teams work together. Connect your electrical and mechanical design teams. Use ECAD-MCAD tools to share data and track changes. Give everyone a clear job so they know what to do. This helps you move fast and make good choices.

Prototypes help you test ideas and show what works. You can try different solutions and change things quickly. This helps you make new medical devices that fit real needs.

You can work faster and better by using vacuum casting and 3d printing services. These methods help medical device companies make accurate prototypes and small batches without spending a lot or waiting long.

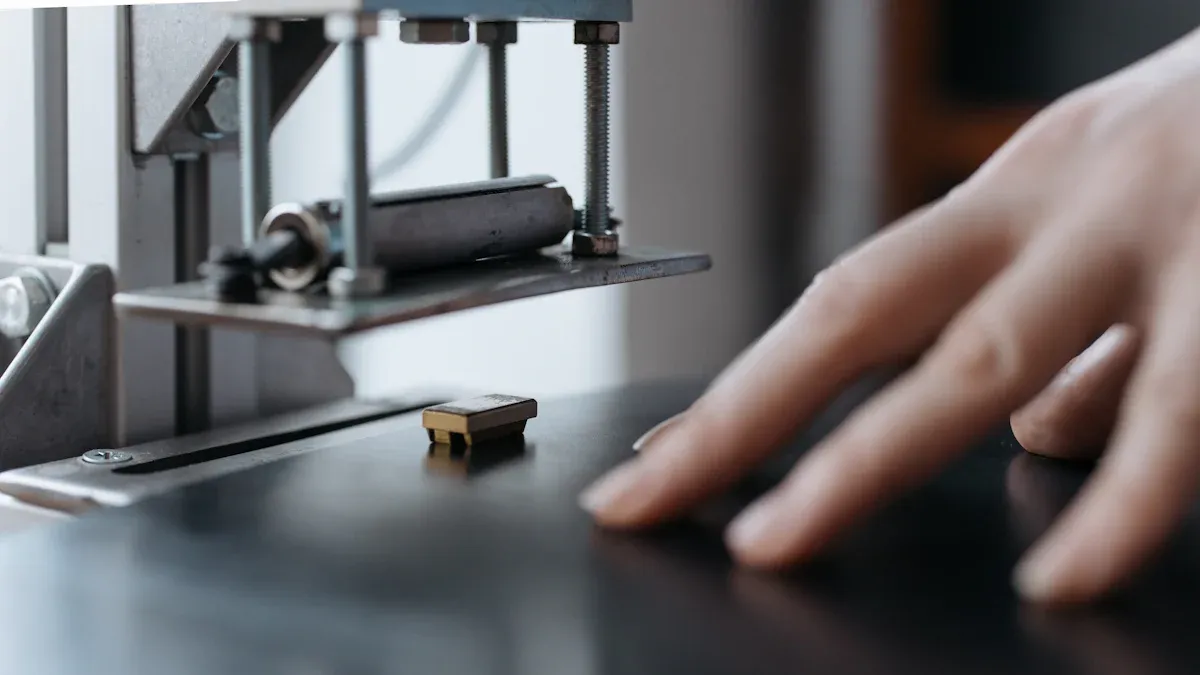

Vacuum Casting

Vacuum casting has many benefits:

High quality and quick results

Saves money for small batches

No need for costly tools

Can copy complex shapes and features

Lets you color resins for different needs

3D Printing Services

3d printing services give you:

Fast and cheap prototypes

No tools needed, so you save money

Can make complex shapes with good accuracy

Quick changes for simple products

Method | Cost-Effectiveness | Turnaround Time |

|---|---|---|

Vacuum Casting | Saves money for small batches, no costly tools needed. | Good for small batches with fine detail. |

3D Printing | Cuts costs, no tools needed, good for small batches. | Fast results for prototypes, easy to change. |

You can use both methods together. For example, use 3d printing to make a master model. Then use vacuum casting to make more copies. This helps medical device companies get fast and high-quality prototypes.

You need a good partner to reach your goals. Kaierwo is a top medical device manufacturer with rapid prototyping and small batch skills. With over 15 years of experience, Kaierwo helps from design to production.

Kaierwo uses advanced machines like 3d printing services and CNC machining centers. This makes every project precise and efficient. The company has ISO 9001:2015 and ISO 13485:2016 certifications. These prove strict quality and safety for medical device companies.

Certification | Description |

|---|---|

ISO 9001:2015 | General quality management standard for all industries. |

ISO 13485:2016 | Medical device-specific standard, ensuring compliance with strict regulations for quality and safety. |

Working with Kaierwo gives you:

Help from start to finish

Advanced 3d printing and CNC machining for custom devices

Solutions that save time and money

High-quality prototypes for patient-specific needs

Teamwork between technologies for better results

Kaierwo helps medical device companies get products to market faster. You can trust their skills to turn ideas into real products and stay ahead in medical innovation.

Rapid prototyping helps medical devices get approved faster. A startup made a brain surgery GUI in eight weeks. This fast work let them answer investor questions quickly. In-house 3D printing gives you parts in days, not weeks. Speed matters in medical devices because every day is important. If you plan for manufacturing and certification early, you avoid last-minute changes. You get a reliable product ready for clinical use. Kaierwo helps companies move from idea to approval faster. They use advanced methods like vacuum casting and 3D printing.

Rapid prototyping saves money when you need small batches. You do not pay for expensive tools or make too many parts. You can test and improve your design with less risk. The table below shows how companies save money:

Cost-Saving Aspect | Description |

|---|---|

Reallocation of Resources | You can spend money on other project needs, not just making parts. |

Lower End-User Costs | Lower costs help patients get your products more easily. |

Shorter Development Cycles | Faster testing means you spend less time and money. |

On-Demand Manufacturing | You only make what you need, so you waste less and save on storage. |

Efficient Small-Batch Production | You can make small amounts without risking too much money. |

You make your device better by testing real models early. Rapid prototyping turns ideas into products in just days. Quick feedback helps you fix problems before making lots of devices. If you let users test your device, you get helpful feedback. This leads to better designs and happier users. Kaierwo’s way helps you improve your device and meet user needs. You get your device to market faster and make it safer and more effective.

Tip: Testing usability early makes better products and happier customers.

Rapid prototyping helps you launch products faster. You get better results and can beat other companies. Working with experts like Kaierwo makes things easier. You save time and get high-quality products. The table below shows how rapid prototyping helps you win:

Competitive Advantage | Description |

|---|---|

Faster Time-to-Market | You launch products quickly and stay ahead of competitors. |

Cost Efficiency | You save money by fixing problems early. |

Early Identification of Flaws | You spot design issues before they become costly. |

Quick Iteration | You improve products fast with real feedback. |

Regulatory Compliance | You meet strict industry standards with ease. |

Kaierwo uses smart ways to help you work better. They use Just-in-Time inventory and keep improving their process. Their team follows clear steps to make work simple. These methods help you waste less and get more done. Look at your process and see how rapid prototyping can help you do better in medical devices.

What is rapid prototyping in medical device manufacturing?

Rapid prototyping helps you make real models from digital plans fast. You can try out ideas and see if they work. It is easy to check if parts fit together. You can fix problems and change designs quickly. This helps you get medical devices to patients sooner.

How does vacuum casting help with small batch production?

Vacuum casting uses silicone molds to make plastic parts. You can make up to 20 pieces before needing new molds. This saves money and time for small batches. It is good if you need to change your design often.

Why should you choose Kaierwo for medical components?

Kaierwo has more than 14 years of experience making medical parts. You get high quality because they have ISO certificates. They use advanced methods like vacuum casting. Kaierwo helps you from the first idea to the finished product. They help you follow strict rules and get your product out faster.

Can rapid prototyping improve regulatory compliance?

Yes! Rapid prototyping lets you test and keep records of every change. You can show proof to regulators that your device is safe and meets rules. This helps you avoid waiting a long time for approval.

What materials can you use for medical prototypes?

Material | Key Benefit |

|---|---|

ABS | Strong and lightweight |

Polypropylene | Flexible and durable |

Aluminum | Lightweight and sturdy |

Stainless Steel | Corrosion-resistant |

You can pick the best material for your device.

Contact Us

Rapid Prototyping CNC LIST

What is Casting? Understanding the Fundamental Metal Forming ProcessRapid Prototyping Industry Glossary: Key Manufacturing Terms ExplainedCost Analysis: CNC Machining vs. 3D Printing in Medical ApplicationsFrequently Asked Questions about Vacuum CastingA Comprehensive Selection Guide For Aluminum Material3D Printing Service FAQsIndustries That Use Aluminum CNC Machining5 Axis Precision Machining ServiceComprehensive Guide to Kaierwo Vacuum Casting ServicesFrom CAD to Reality: How Rapid Prototyping with Additive Manufacturing WorksA Complete Guide to CNC MachiningCNC Milling and Turning ServicesCNC Machining Aluminum and Plastic Services3D Printing Complete GuideCNC Milling Service CompanyVacuum Casting Surface Treatment Processes and IntroductionPlastic Injection Mold Making and Custom Casting MoldsRapid Tooling Service CompanyRapid Prototyping Manufacturer|KaierwoCNC Machine Shop Precautions: A Practitioner’s Best-Practice PlaybookHow companies use rapid prototyping to shorten development timePrototype Manufacturing Technologies & Tools: A Complete GuideCNC Turning Service Company|KaierwoThe Role of 3D Printing in Personalized Healthcare SolutionsComprehensive Guide to 3D Printing Surface Finishing MethodsCNC Machining Services ManufacturerThe Advantages of 3D Printing ServicesCommon Vacuum Casting Industry TermsSheet Metal Fabrication Services|KaierwoWhy Aluminum is an Essential Material in CNC Machining?How to Reduce Lead Time in Rapid Prototyping Additive Manufacturing ProjectsFrequently Asked Questions about CNC MachiningComprehensive Aluminum Processing FAQ5 Axis Machining Services|Kaierwo3D Printing Die Casting: Revolutionizing Manufacturing ProcessesComplete Guide to 3D Printing MaterialsDie Casting Service Supplier|KaierwoHow to ensure your rapid prototype meets the final product specificationsFDM (Fused Deposition Modeling) 3D PrintingAluminum CNC Machining Standard Hole SizesCNC Machining Applications Across IndustriesPrecision Aluminum Machining ServicesHow to Validate a Medical Prototype Before Production?The Complete Guide to Vacuum CastingKaierWo Offers Efficient Low-Volume CNC Machining Services