We attach great importance to customers' needs for product quality and rapid production.

We always insist that meeting customers' needs is to realize our value!

+86 133 9281 9446

Industrial equipment requires durable, precise, and reliable components to operate under demanding conditions. From heavy-duty structures to precision mechanical parts, Kaierwo provides CNC machining and manufacturing solutions that support industrial equipment manufacturers throughout the product lifecycle.

We help customers turn complex designs into high-quality parts with stable performance, supporting both prototyping and low-volume production.

Carbon Steel

High strength and cost-effective. Commonly used for structural components, frames, and mechanical parts that require durability.

Stainless Steel

Excellent corrosion resistance and mechanical strength. Suitable for shafts, brackets, housings, and components exposed to harsh environments.

Aluminum

Lightweight and easy to machine. Widely used for frames, enclosures, and parts where weight reduction and corrosion resistance are required.

Alloy Steel

Enhanced mechanical properties such as hardness and fatigue resistance. Often applied in gears, transmission parts, and load-bearing components.

Brass & Copper

Good electrical and thermal conductivity. Used for connectors, bushings, and conductive components in industrial systems.

Engineering Plastics (POM, Nylon, ABS)

Used for gears, guides, covers, and non-metallic components that require wear resistance and dimensional stability.

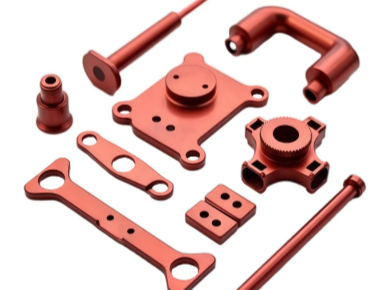

CNC Machining (Metal & Plastic)

Manufacturing of shafts, frames, brackets, housings, and functional mechanical parts.

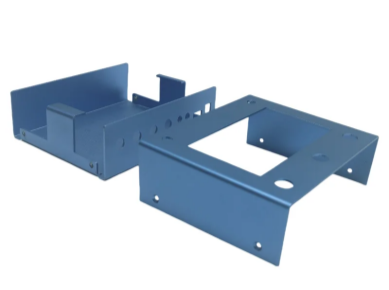

Panels, frames, covers, and enclosures for industrial machinery and equipment systems.

Quick functional prototypes for equipment testing and optimization.

Small-batch production to support customized equipment and pilot projects.

Surface Treatment & Assembly Support

Enhancing durability and performance for industrial applications.

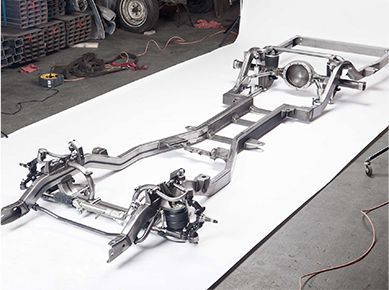

Machine frames and structural components

Shafts, gears, and transmission parts

Brackets, mounts, and support structures

Equipment housings and enclosures

Automation and production line components

Custom mechanical parts

Why Choose Kaierwo For Industrial Equipment Manufacturing?

1.Engineering-Oriented Support

Kaierwo provides strong engineering support throughout your project. Our team reviews part structures, tolerances, load requirements, and material selection to ensure components perform reliably in industrial environments. We help optimize designs for machinability, strength, and cost efficiency, reducing production risks and improving long-term performance.

2.Capability For Complex & Large Parts

Industrial equipment often involves complex geometries and large-sized components. Kaierwo is equipped to handle multi-face machining, deep cavities, and heavy-duty structures. Our CNC capabilities allow us to maintain stable accuracy even for large or complex parts, ensuring proper assembly and functional reliability.

3.Flexible Production Capacity

We support industrial equipment projects from functional prototypes to low-volume production. Whether you need a single custom component or small-batch manufacturing, Kaierwo adapts quickly to changing requirements while maintaining consistent quality and delivery schedules.

4.Consistent Quality & Inspection

Quality and reliability are critical in industrial applications. Kaierwo follows standardized machining processes and strict inspection procedures to ensure dimensional accuracy and repeatability. Each part is carefully checked using professional measuring equipment to meet your technical and performance requirements.

Reviews

Mechanical Engineer, Industrial Equipment Manufacturer

“Kaierwo supported our industrial equipment project with CNC machining for structural and load-bearing components. The parts met our dimensional and strength requirements, and their engineering team provided practical suggestions to improve manufacturability. Overall quality and delivery were reliable.”

Project Manager, Industrial Machinery Company

“We have worked with Kaierwo on several custom industrial parts for our machinery systems. Their ability to handle complex geometries and maintain consistent quality across batches made them a dependable manufacturing partner. Communication and technical support were professional throughout the process.”

Certifications

We use advanced metrology equipment to verify all incoming raw materials and will provide you full certificates of compliance for your peace of mind. Our metrology equipment includes Roughness, Vernier calipertester, Micrometer, etc. More information about our enquipment please read our page Quality Inspection. Our facility is fully certified to ISO13485:2016, ISO9001:2015, etc

1.OUR FACTORY VIDEO

More Industries we work with

Medical Devices

Transprent parts

Aluminum parts

We attach great importance to customers' needs for product quality and rapid production.

We always insist that meeting customers' needs is to realize our value!