-

+86 133 9281 9446

+86 133 9281 9446

CNC machining uses computer-controlled tools to shape materials by removing excess material, creating parts with high precision. You benefit from this technology because it delivers consistency and flexibility in producing complex parts for modern manufacturing. Recent industry reports show that cnc operations account for a large share of global revenue due to their accuracy and efficiency.

Segment | Key Features |

|---|---|

CNC Operation | 78.5% of global revenue in 2023; high precision, efficiency, scalability |

Milling Machining | Versatile; handles many materials and complex shapes |

Laser Machining | Ideal for delicate, precise work with minimal waste |

Automotive Segment | Largest share; essential for precise engine and transmission components |

You will find clear, practical answers to your most Frequently Asked Questions about cnc machining in the sections below.

You may encounter the term CNC often in manufacturing discussions. CNC stands for Computer Numerical Control. This technology uses computers to control machine tools and automate the process of shaping materials. CNC machining is a subtractive manufacturing process. You start with a solid block, called a workpiece or blank. The machine removes layers from this block to create a custom part. You can use CNC machines with metals, plastics, wood, glass, foam, and composites. This versatility makes CNC essential for modern manufacturing.

CNC machines follow programmed instructions. You do not need to guide the tool by hand. The computer ensures each movement is precise and repeatable. This process allows you to produce complex shapes and tight tolerances that manual methods cannot achieve. When you look for answers to frequently asked questions about CNC, you will find that accuracy, speed, and flexibility are the main reasons for its popularity.

Tip: CNC machining gives you the ability to make parts with consistent quality, even for large production runs.

You might wonder about the difference between CNC and NC. Both terms refer to machines that use numerical control, but they have key differences.

Feature | CNC Press Brakes | NC Press Brakes |

|---|---|---|

Automation | High automation with advanced programming capabilities | More manual control, less automated |

Flexibility | Less flexible, suited for mass production | Highly flexible, ideal for bespoke projects |

Application Scope | Broader, suitable for complex and high-efficiency tasks | Narrower, best for simple or one-off projects |

CNC machines use computers to store and execute programs. You can change the program easily to make different parts. This makes CNC ideal for industries that need high efficiency and complex designs. NC machines rely on manual input or punched tape. You have less automation and flexibility with NC. Most modern factories use CNC because it saves time and reduces errors.

When you review frequently asked questions about CNC, you will see that automation and flexibility are major advantages. CNC machines let you switch between jobs quickly. You can handle both small batches and mass production with the same equipment.

You will find CNC machines in almost every major industry. These machines help you create parts that require high precision and reliability. Here are some of the most common applications:

Aerospace: You use CNC to make turbine blades, landing gear, and other high-precision components.

Renewable Energy: CNC machines produce parts for wind turbines and solar power systems.

Robotics and Automation: You rely on CNC for robotic arms, sensors, and automation parts.

Medical and Dental: CNC machining creates surgical implants and tools from biocompatible materials.

Electronics: You use CNC to manufacture heat sinks and intricate electronic components.

Tooling and Industrial Machinery: CNC machines make custom tools and heavy-duty machine parts.

Consumer Goods: You see CNC in luxury watches and high-quality everyday products.

Agriculture: CNC machining produces parts for farm machinery.

Energy Industry: CNC machines create components for pipelines and energy production systems.

Sector | Applications |

|---|---|

Aerospace | High-precision components like turbine blades and landing gear, using exotic materials. |

Renewable Energy | Components for wind turbines and solar power systems, ensuring durability and precision. |

Robotics and Automation | Parts such as robotic arms and sensors, essential for automation technologies. |

Medical and Dental | Surgical implants and tools made from biocompatible materials, ensuring precision and reliability. |

Electronics | Production of heat sinks and intricate components for electronic devices. |

Tooling and Industrial Machinery | Custom tooling and heavy-duty machinery components, ensuring accuracy and longevity. |

Consumer Goods | High-end products like luxury watches and everyday items, crafted for quality and design. |

Agriculture | Components for farm machinery, providing high precision and durability. |

Energy Industry | Parts for wind turbines and oil/gas pipelines, crucial for energy production. |

You may ask why CNC is so widely adopted. Several factors drive this trend:

Technological advancements, such as Industry 4.0 and smart factory solutions.

The need for high-precision, automated machining centers in industries like automotive and aerospace.

Digitalization and IoT connectivity, which improve efficiency and product quality.

Real-time data for process analysis and predictive maintenance.

The rise of automated manufacturing systems, robotics, and advanced control systems.

Integration of Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) systems.

When you explore frequently asked questions about CNC, you will notice that these factors make CNC machines essential for modern production. You gain improved quality, consistency, and lower operating costs. The market for CNC machining continues to grow, showing its importance in global manufacturing.

Note: CNC machines help you meet strict industry standards and deliver reliable results across many sectors.

If you have more frequently asked questions about CNC, keep reading the next sections for deeper insights into the process, materials, and best practices.

You start the cnc machining process by turning a digital design into a real part. This process uses a computer to control the machine and guide every movement. You create a 3D model of your part using CAD software. The software defines the size, shape, and features of your part. Next, you use CAM software to convert this model into a set of instructions. These instructions tell the machine how to move, what tools to use, and how much material to remove.

The machine follows these instructions to cut, drill, or shape the material. You can use metals, plastics, or composites. The machine removes material layer by layer until the part matches your design. Throughout the process, you monitor the machine to ensure accuracy. You check the finished part for quality and precision. This method allows you to produce complex parts with tight tolerances and repeatable results.

Tip: CNC machining gives you the ability to make parts with high precision and consistent quality, even for large production runs.

You have access to several types of cnc machines, each designed for specific tasks. The table below shows the main types, their strengths, and typical applications:

Type of CNC Machine | Strengths | Applications | Speed | Cost |

|---|---|---|---|---|

CNC Milling Machines | Intricate 3D shapes | Parts with slots, pockets, engravings | Varies | High |

CNC Lathes | Cylindrical & spherical parts | Shafts, gears, bearings | High | Mid-range |

CNC Drilling Machines | Precise holes | Electronics, circuit boards, furniture | Moderate | Low |

CNC Plasma Cutters | Fast, High-Volume | Sheet Metal, Signage | High | Lower |

CNC Laser Cutting Machines | Precision & Intricate Cuts | Electronics, Delicate Metalwork | Moderate | Mid-Range to High |

CNC Router Machines | Versatile for various materials | Woodworking, intricate designs | High | Varies |

CNC EDM Machines | Highly precise machining | Hard metals, exotic alloys | Moderate | High |

CNC Waterjet Cutting Machines | No heat-affected zone | Sensitive materials | Moderate | Mid-Range |

CNC milling machines help you create complex shapes and surfaces. CNC lathes work best for round or cylindrical parts. Drilling machines automate the process of making holes with high accuracy. Plasma and laser cutters offer speed and precision for cutting sheet materials. Routers handle wood, plastics, and soft metals. EDM machines allow you to machine hard metals with extreme accuracy. Waterjet machines cut sensitive materials without heat.

Learn more about our CNC Milling Services to see how you can benefit from advanced machining solutions.

You follow a series of steps to turn your design into a finished part. Here is a typical workflow:

Design & CAD

CAM Programming

Setup & Operation

You begin by designing your part in CAD software. You define every detail, including dimensions, surface finish, and material type. This digital model serves as the blueprint for the entire process. You can make changes easily at this stage, which helps you optimize your design for manufacturability.

Next, you use CAM software to create the machining program. The software analyzes your CAD model and generates toolpaths. These toolpaths tell the machine how to move and what tools to use. You select cutting tools and set parameters like speed and feed rate. The CAM program converts your design into a language the machine understands.

You prepare the machine by installing the correct tools and loading the material. You position the workpiece and set the machine’s coordinate system. You load the program and run a test to check for errors. Once everything is ready, you start the machining process. The machine follows the program to shape the part. You monitor the process to ensure quality and make adjustments if needed. After machining, you inspect the part for accuracy and finish.

Note: Quality control is essential at every step. You check dimensions and surface finish to ensure the part meets your requirements.

This step-by-step approach allows you to achieve high precision and repeatability in every part you produce. The cnc machining process gives you control over every detail, from design to finished product.

You rely on cnc machining when you need high precision and accuracy in your parts. The machine uses computer control to guide every movement, which means you get consistent results every time. This level of control is not possible with manual machining. You can achieve tight tolerances, often within a few microns, which is essential for industries like aerospace and medical device manufacturing.

CNC machines provide precise control over cutting tools and workpieces, ensuring consistent accuracy.

They excel in repeatability, allowing for high precision across multiple workpieces.

Once programmed correctly, cnc machines maintain tight tolerances consistently.

CNC machining outperforms manual machining in consistency, cost-efficiency, quality, and reliability.

You can trust cnc machining to deliver parts that meet strict industry standards. When you work with metal, you need to know that every cut and hole is exactly where it should be. This is why cnc is the preferred choice for high precision applications.

Repeatability measures how well a machine can produce the same result over and over. In cnc machining, this means you can make hundreds or thousands of identical parts without variation. This is important for mass production, where every part must fit and function perfectly.

Repeatability refers to the consistency of outcomes when the same operation is performed multiple times under identical conditions. This concept is crucial in cnc machining as it directly impacts the precision of the machining process.

A cnc turning center has a positioning accuracy of 0.010mm.

The repeatability of this machine is 0.002mm.

This means that while the machine may position itself within a range of 10 microns, it will consistently repeat that positioning error within 2 microns.

In practice, a cnc machine with a repeatability of 0.002mm can machine a diameter with a tolerance of +/- 0.006mm. Even if the first part is slightly out of tolerance, the following parts will stay within a predictable range. This level of control is vital for industries that demand high precision and reliability.

Cnc machining gives you significant efficiency gains compared to traditional methods. The machine automates production, so you spend less time on manual labor and more time on value-added tasks. You can run the machine for long hours with minimal supervision, which increases your throughput and reduces lead times.

CNC machining provides unmatched precision and repeatability, essential for high-quality manufacturing.

It enables faster production cycles, which reduces lead times and increases throughput.

The automation of cnc machining leads to lower labor costs, as less manual intervention is required.

CNC machining automates production, ensuring each part meets the specified design.

This uniformity is particularly beneficial in industries like automotive and electronics, enhancing manufacturer reputation and customer trust.

While cnc machining may be more costly for small jobs, it offers significant efficiency and cost savings for larger production runs.

The ability to produce identical parts easily makes it ideal for high-volume manufacturing.

You benefit from the ability to produce large quantities of metal parts quickly and accurately. This efficiency helps you stay competitive in fast-paced industries.

You gain a significant advantage with CNC machining because of its unmatched flexibility. This flexibility allows you to adapt quickly to changing design requirements, material choices, and production volumes. When you need to create custom parts or handle complex geometries, CNC technology gives you the tools to do so efficiently.

CNC machines can switch between different tasks with minimal downtime. You can reprogram a machine to produce a new part in minutes. This capability supports rapid prototyping and short production runs. You do not need to invest in new tooling for every design change. Instead, you update the digital program and let the machine handle the rest.

The flexibility of CNC machining comes from several advanced features. The table below highlights key aspects that make this process ideal for custom and complex part production:

Aspect | Description |

|---|---|

Advanced Techniques | CNC machining employs advanced techniques that allow for intricate designs and tight tolerances. |

Multi-Axis Capabilities | The ability to use multiple axes reduces the number of setups required for complex parts. |

Custom Engineering Solutions | Tailored solutions enable the production of highly complex and custom CNC parts efficiently. |

Tolerance and Finish | CNC machining can achieve tight tolerances and high-quality surface finishes comparable to grinding. |

You can use a multi-axis machine to create parts with complex curves and angles. This reduces the need for multiple setups and manual intervention. You save time and improve accuracy. When you need a custom engineering solution, CNC machining adapts to your requirements. You can produce one-off prototypes or scale up to full production without changing the core process.

CNC machines also support a wide range of materials. You can work with metals, plastics, composites, and specialty materials. This flexibility lets you choose the best material for your application. You can achieve tight tolerances and smooth surface finishes, even on challenging designs.

Here are some ways CNC machining delivers flexibility in your projects:

You can modify designs quickly and test new ideas without extra cost.

You can produce both simple and highly complex parts on the same machine.

You can handle urgent orders or last-minute changes with minimal disruption.

You can maintain consistent quality across different materials and part geometries.

Tip: Use CNC machining when you need to respond quickly to market demands or customer requests. The technology helps you stay competitive by reducing lead times and supporting innovation.

CNC machines empower you to meet diverse manufacturing needs. Whether you work in aerospace, medical devices, or consumer products, you benefit from the ability to adapt and deliver precise results. Flexibility in machining ensures you can tackle any challenge, from prototyping to full-scale production.

Selecting the right materials is essential for achieving optimal results in cnc machining. You need to consider the properties of each material, the requirements of your application, and the capabilities of your machine. The choice of material affects the performance, durability, and cost of your finished part. Below, you will find an overview of the most common metals, plastics, and other materials used in cnc machining.

Metals remain the most widely used materials in cnc machining. You benefit from their strength, durability, and versatility. Each metal offers unique properties that suit specific industries and applications.

You often choose aluminum for cnc machining because it combines low density with high strength. This metal is easy to machine and provides excellent corrosion resistance. You will find aluminum parts in transportation, construction, aerospace, packaging, and electronics. Alloys such as 6061 and 7075 are popular for their machinability and strength.

Steel is a top choice when you need toughness and wear resistance. Alloy steel works well for parts that must handle heavy loads. Stainless steel alloys provide corrosion resistance, making them ideal for food processing and medical devices. Nitronic 60, a stainless steel variant, offers enhanced strength and wear resistance, especially in marine environments.

Brass and copper stand out for their machinability and electrical properties. You use brass in musical instruments, plumbing fittings, and electrical components. Copper is essential for valves and electronics due to its high thermal and electrical conductivity. Bronze, another copper alloy, is valued for bushings, bearings, and electrical contacts.

Tip: When you select a metal, consider the required strength, corrosion resistance, and conductivity for your application.

Common Metals and Their Applications:

Aluminum: Aerospace, automotive, electronics, packaging

Brass: Plumbing, electrical, musical instruments

Bronze: Bearings, bushings, electrical contacts

Copper: Electronics, valves

Nickel Alloys: Aerospace, petrochemical

Stainless Steel: Medical, food processing

Titanium Alloys: Aerospace, medical implants

Alloy Steel: Heavy-duty parts

Plastics offer unique advantages in cnc machining. You benefit from their light weight, corrosion resistance, and insulating properties. Plastics also allow for faster machining speeds and less tool wear compared to metals.

ABS is a popular plastic for cnc machining. You use it for prototypes, enclosures, and consumer products. ABS provides good impact resistance and machinability. It is also easy to finish and paint.

Nylon stands out for its toughness and wear resistance. You find nylon parts in gears, bushings, and automotive components. Nylon resists abrasion and has good chemical stability.

Polycarbonate is known for its strength and transparency. You use it in safety equipment, lenses, and electronic housings. Polycarbonate withstands impact and offers excellent electrical insulation.

Advantages and Limitations of Plastics in CNC Machining:

Advantages | Disadvantages |

|---|---|

Fast machining speeds | Lower strength and hardness |

Less tool wear | High thermal expansion |

Light weight | Surface quality |

Good corrosion resistance | Poor temperature resistance |

Excellent insulation |

Plastics resist scratching, impact, and corrosion.

Some plastics withstand temperatures above 500°C.

You benefit from excellent electrical and thermal insulation.

You may require materials beyond metals and plastics for specialized applications. Composites and specialty options expand your possibilities in cnc machining.

Composites such as carbon fiber and fiberglass combine strength with low weight. You use carbon fiber in aerospace, automotive, and sporting goods for its high strength-to-weight ratio. Fiberglass is common in boat hulls, automotive parts, and electrical enclosures.

Specialty materials include carving foam for marine applications and phenolics for electrical uses. These materials allow you to meet unique industry requirements. Plastics are also used in medical and defense sectors.

Material | Industries Used |

|---|---|

Plastics | Medical, Defense |

Carving Foam | Marine |

Phenolics | Electrical applications |

Carbon Fiber | Aerospace, Automotive, Sporting Goods |

Fiberglass | Boat hulls, Automotive parts, Electrical enclosures |

Explore available Machining Materials to find the best fit for your next cnc project.

Material Comparison Table:

Material Type | Strength | Weight | Machinability | Corrosion Resistance | Typical Use Cases |

|---|---|---|---|---|---|

Aluminum | Medium | Low | High | High | Aerospace, Electronics |

Steel | High | High | Medium | Medium-High | Automotive, Medical |

Brass/Copper | Medium | Medium | High | High | Electrical, Plumbing |

ABS | Low | Low | High | High | Prototyping, Consumer |

Nylon | Medium | Low | High | Medium | Gears, Bushings |

Polycarbonate | Medium | Low | Medium | High | Safety, Electronics |

Carbon Fiber | High | Very Low | Medium | High | Aerospace, Sporting Goods |

You should always match your material choice to your design, performance, and cost requirements. The right selection ensures your cnc machining project meets industry standards and delivers reliable results.

Material selection plays a major role in the total cost of cnc projects. You need to consider several factors when choosing materials for machining. The price of raw materials can vary widely. For example, titanium costs five to ten times more than carbon steel. Machinability also affects cost. Some materials, such as 316 stainless steel, require slower cutting speeds than aluminum. This increases labor time and machine use. Tool wear rates differ as well. Inconel and other tough alloys can wear down tools quickly, leading to higher replacement costs. Material waste is another factor. By optimizing your design and nesting parts efficiently, you can reduce waste by 20 to 40 percent. Some materials need extra post-processing, which adds time and expense. High-performance materials may increase your costs by 200 to 500 percent due to their unique properties.

Choosing the right material can save you money. If you select 6061-T6 aluminum or 1018 carbon steel, you can lower both material and machining costs. These choices often reduce total project expenses by 30 to 50 percent. High-performance materials like titanium offer strength but raise costs because of their price and lower machinability.

Raw material price

Machinability and cutting speed

Tool wear and replacement

Material waste and optimization

Post-processing needs

Performance specifications

Tip: Always balance performance requirements with cost when selecting materials for cnc machining.

The complexity of your part has a direct impact on cnc costs. Simple parts require fewer process steps and less machine time. Complex parts need more operations, advanced machines, and skilled operators. Each added feature, such as tight tolerances, deep cavities, or intricate geometries, increases the number of process steps. You may need larger or more capable machines for these tasks. These machines cost more to operate and maintain. Complex parts also require experienced operators to manage the risks and ensure quality.

More complex parts increase the number of required process operations.

Advanced machines and skilled operators are necessary for intricate designs.

Projects with high complexity take longer to complete and cost more.

You should consider simplifying your design where possible. Reducing unnecessary features can help control costs and speed up production.

Order quantity strongly affects the per-unit cost in cnc machining. Setup and tooling expenses remain fixed, regardless of how many parts you produce. When you order a higher volume, you spread these costs over more units, lowering the price per part. Bulk material purchases can also lead to discounts. For low-volume orders, the per-unit cost stays high because you cannot distribute setup costs as effectively.

Production Volume | Cost Implications | Strategies to Optimize |

|---|---|---|

High Volume | Lower per-unit cost due to distributed setup expenses. Bulk material discounts. | Invest in high-capacity machines. Standardize designs. |

Medium Volume | Moderate per-unit cost, balancing setup and output. | Use versatile machines for various parts. |

Low Volume | High per-unit cost from fixed setup and tooling. | Simplify designs to reduce setup complexity. |

You can optimize costs by planning production runs and standardizing part designs. High-volume orders benefit most from cnc efficiency, but even small batches can be cost-effective with smart design choices.

Tolerances define the allowable variation in a part’s dimensions. You specify tolerances to ensure that each part fits and functions as intended. In CNC machining, tighter tolerances mean the machine must cut closer to the exact size, leaving less room for error. This requirement affects both the process and the cost of your project.

When you request tighter tolerances, the machine must perform multiple cutting operations with different tools. Each pass removes a small amount of material to approach the final dimension. The machine slows down to maintain accuracy, which increases machining time. You may also need higher-grade materials and specialized tooling. These tools wear out faster because the machine works with greater precision. As a result, you see higher costs for both labor and equipment.

Certain design features, such as sharp internal corners, make it harder for the machine to achieve the required tolerances. The machine may need to use smaller tools or additional setups, which adds complexity. You also face more frequent quality inspections. The machine operator must check each part carefully to confirm it meets your specifications. This process slows down production and increases labor costs.

Manufacturing parts with very tight tolerances can double or even quadruple your costs. For example, if you tighten accuracy to 0.005 inches, the machine requires more time and tool changes. At 0.001 inches, costs rise even further. The need for advanced CNC machine equipment becomes critical. You invest in machines with higher precision and stability. The increased frequency of inspections adds to your overall expenses.

Tip: Specify the loosest tolerance that still meets your functional requirements. This approach helps you control costs and speeds up production.

You should also consider industry standards when setting tolerances. ISO 2768 and ASME Y14.5 provide guidelines for general tolerances in CNC machining. These standards help you balance quality and cost. By following them, you ensure that your parts meet industry expectations without unnecessary expense.

Key Points to Remember:

Tighter tolerances require more machine time and specialized tools.

Complex features increase machining difficulty and cost.

Frequent inspections slow production and raise labor costs.

Advanced machine equipment is necessary for extreme precision.

Costs can double or quadruple as tolerances become tighter.

Choosing the right tolerance is a critical step in your CNC machining project. You achieve the best results when you match your tolerance requirements to your application’s needs and the machine’s capabilities.

You want to know how long it takes to receive finished parts from a cnc machining provider. Typical turnaround times for reputable companies range from 4 to 6 weeks. This estimate covers most standard projects. Simple parts may be ready in just a few hours. Complex components with tight tolerances or special materials can take several weeks. The actual lead time depends on the complexity of your design, the material you select, and the current workload at the machining facility.

You should always confirm the expected delivery date when you request a quote. Some providers offer expedited services for urgent projects. These services may reduce lead times but can increase costs. Planning ahead helps you avoid delays and ensures your project stays on schedule.

Several factors influence how quickly you receive your cnc parts. The table below highlights the most significant elements that impact machining lead times, based on industry surveys:

Factor | Description |

|---|---|

Aerospace & Defense | High demand for precision components increases machine utilization and can extend lead times. |

Medical Device Manufacturing | Complex parts and strict standards require more time for machining and inspection. |

Space Exploration | Specialized machining services for unique parts may lengthen production schedules. |

Reshoring Initiatives | Increased domestic demand can strain available machine capacity. |

Cybersecurity Requirements | Certified services add steps to the process, affecting overall timing. |

Number of Businesses | The number of certified shops determines available machining capacity. |

Equipment Investment | Newer machines and technology can speed up production. |

Skilled Labor | A shortage of experienced machinists may slow down operations. |

Supply Chain Disruptions | Delays in material delivery can impact the start of machining jobs. |

Cybersecurity Infrastructure | Meeting security standards adds complexity to scheduling and planning. |

You see that both internal and external factors affect how quickly a machine shop can deliver your order. The availability of skilled machinists, investment in advanced machines, and the stability of the supply chain all play important roles.

You can take several steps to reduce cnc machining lead times without sacrificing quality. Consider these proven strategies:

Strategy | Description |

|---|---|

Automation | Automated machines run longer hours with fewer interruptions, speeding up production. |

Robotic Loading and Unloading | Robots handle repetitive tasks, allowing machines to operate continuously and efficiently. |

Lean Manufacturing Principles | Streamlined workflows eliminate wasted time and improve overall efficiency. |

Optimizing Cutting Parameters | Adjusting speeds and feeds for each material and machine maximizes productivity. |

Smart Design Selection | Simple, well-designed parts reduce setup and machining time. |

Submit clear and complete CAD files to your provider.

Choose standard materials that are readily available.

Specify only the tolerances and finishes you truly need.

Communicate your deadlines early in the process.

Ask about expedited options if your project is urgent.

Tip: Early collaboration with your cnc provider helps identify potential bottlenecks and ensures a smoother production process.

By understanding these factors and applying best practices, you can achieve faster turnaround times and keep your projects on track.

When you work with cnc machining, understanding tolerances is essential. Tolerances define how much a part’s dimensions can vary from the design. You use tolerances to ensure that every part fits and functions as intended. The right tolerance helps you balance quality, cost, and production speed.

Most cnc machining projects follow standard tolerances. These tolerances depend on the process, material, and machine capability. For reference, the thickness of a human hair is about 0.002 inches (0.05 mm). Standard cnc machining tolerances are usually much tighter.

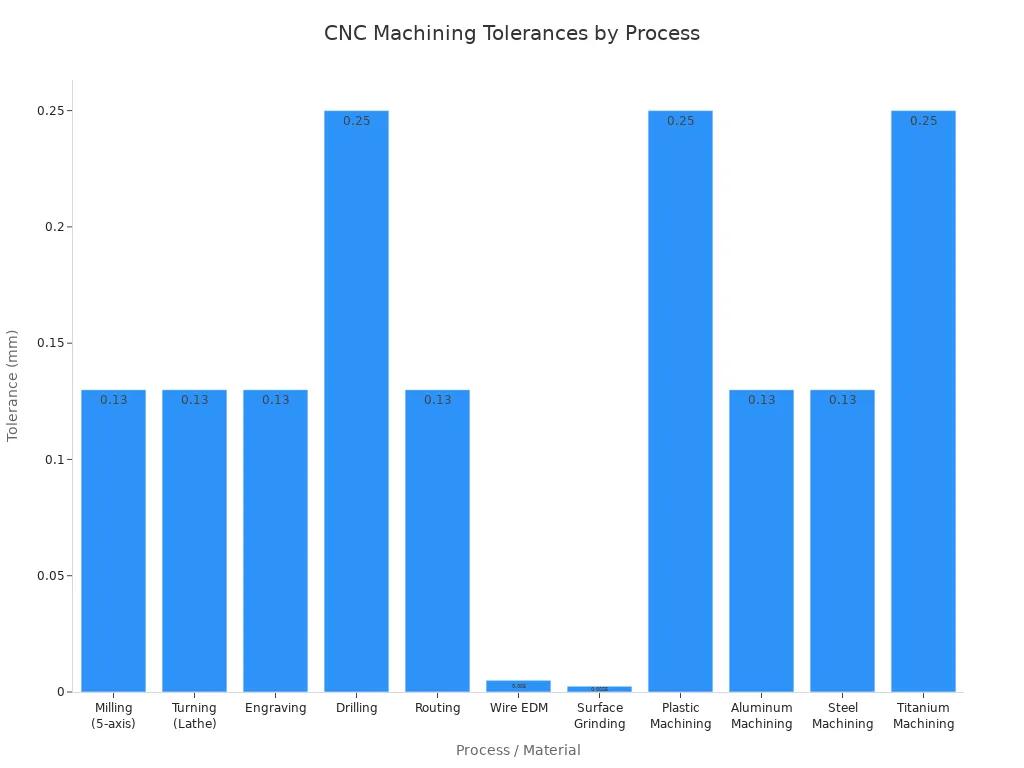

Process | Tolerance |

|---|---|

Milling (5-axis) | ±0.005″ (0.13 mm) |

Turning (Lathe) | ±0.005″ (0.13 mm) |

Engraving | ±0.005″ (0.13 mm) |

Drilling | ±0.010″ (0.25 mm) |

Routing | ±0.005″ (0.13 mm) |

Wire EDM | ±0.0002″ (0.005 mm) |

Surface Grinding | ±0.0001″ (0.0025 mm) |

Plastic Machining | ±0.010″ (0.25 mm) |

Aluminum Machining | ±0.005″ (0.13 mm) |

Steel Machining | ±0.005″ (0.13 mm) |

Titanium Machining | ±0.010″ (0.25 mm) |

You can see these tolerances visually in the chart below:

For most cnc projects, you will find a standard tolerance limit of ±0.005” (0.127 mm). This level of precision meets the needs of many industries, from automotive to consumer electronics.

Several factors affect the tolerances you can achieve with cnc machining. The type of machine, the material, and the process all play a role. You need to consider these factors when planning your project.

Factor | Description |

|---|---|

Machine Rigidity | Resistance to deflection under cutting forces. |

Thermal Stability | Consistency of dimensions despite temperature changes. |

Toolpath Strategy | Appropriate cutting approaches for feature types. |

Cutting Parameters | Speed, feed, and depth settings optimized for precision. |

Workholding Methods | Secure fixturing that minimizes vibration. |

Tool Condition Monitoring | Real-time adjustment for tool wear compensation. |

High-precision machining centers help you maintain tighter tolerances than basic equipment.

Premium solid carbide end mills allow you to reach tolerances as tight as ±0.02 mm for aerospace components.

The way you hold the workpiece in the machine affects vibration and accuracy.

Temperature changes can cause materials to expand or contract, impacting the final size.

You should always match your machine and process to your tolerance needs.

Tight tolerances become critical in industries where every micron counts. You see this in aerospace, medical devices, and electronics. In these fields, even a small deviation can lead to failure or safety risks.

Industry | Tolerance Requirement |

|---|---|

Aerospace | ±0.013 mm (±0.0005") or tighter |

Medical Devices | |

Electronics | Critical performance |

Cnc machining can achieve tolerances as tight as ±0.0005 inches.

You need these tolerances to ensure parts fit perfectly and perform reliably.

In aerospace, a small error can affect flight safety.

Medical devices require life-saving accuracy.

Electronics depend on precise connections for performance.

Tip: Always specify the loosest tolerance that meets your requirements. Tighter tolerances increase cost and production time.

When you understand cnc tolerances, you make better decisions for your project. You ensure quality, control costs, and deliver parts that meet industry standards.

You improve manufacturability by designing parts that align with standard machine capabilities. When you use consistent radii and avoid unnecessary ornamental curves, you reduce tool changes and speed up production. Aligning curved features with standard tooling also helps you achieve better results. Breaking complex curves into simpler geometric segments makes the machining process more efficient.

Feature orientation plays a key role. Parts that require five-axis operations cost more and take longer to produce than those suitable for three-axis machines. You should design parts that fit within the standard work envelope of your machine. This approach reduces complexity and keeps costs under control.

Feature Type | Minimum Radius | Recommended Radius | Manufacturing Benefit |

|---|---|---|---|

Internal corners | 0.005" (0.13mm) | 0.030" (0.76mm) | Standard tooling compatibility |

Deep pockets | 0.010" (0.25mm) | 0.060" (1.52mm) | Reduced tool deflection |

Thin wall features | 0.020" (0.51mm) | 0.080" (2.03mm) | Improved rigidity during cutting |

Tip: Use consistent radii and avoid unnecessary curves to minimize errors and reduce machining time.

Understanding feature limits ensures your design can be produced accurately on a cnc machine. Each machine has a maximum part size, usually defined by its work envelope. For example, a typical cnc machine supports parts up to 40 inches by 20 inches by 20 inches. High-precision machines can create features as small as 0.005 inches in diameter. Weight capacity also matters, as most machines can handle several tons, but you should always check your provider’s specifications.

Feature Type | Description |

|---|---|

Tolerance Grades | Range from IT01 (very high precision) to IT18 (low precision) |

Maximum Part Size | Determined by machine’s work envelope, e.g., 40" x 20" x 20" |

Minimum Feature Size | High-precision machines: as small as 0.005 inches in diameter |

Weight Capacity | Varies by machine, typically supports several tons |

Geometry Constraints | Complexity may require redesign or alternative machining methods |

Tip: Design features within the standard limits of your cnc equipment to avoid costly redesigns and delays.

Material selection directly affects the performance, cost, and efficiency of your cnc project. Some materials, like aluminum, offer high machinability and allow for faster cutting speeds. Softer metals reduce tool wear and help you achieve smoother surface finishes. Harder metals, such as titanium, require slower speeds and more frequent tool changes, which increases production time and expenses.

The choice of material impacts machining expenses, as some materials require more time and labor to machine effectively.

Material availability can affect project timelines, as hard-to-find materials may delay production.

Selecting materials with advanced properties can unnecessarily increase costs, while choosing the lowest cost material that meets design requirements can minimize expenses.

Tool wear is influenced by the hardness and abrasiveness of the material, affecting production efficiency and maintenance costs.

Engineers should consider not only mechanical properties but also machinability, thermal conductivity, and material cost when selecting materials for cnc machining.

Tip: Choose the lowest cost material that meets your design requirements to optimize both performance and budget.

By following these machining design tips, you ensure your parts are easy to manufacture, meet precision standards, and stay within budget. If you need expert guidance, precision machining services can help you optimize your designs for the best results.

Designing for cost efficiency in cnc machining requires a strategic approach. You can achieve significant savings by understanding how design choices impact both setup and production costs. Intelligent Design for Manufacturing (DFM) helps you optimize every stage, from initial concept to finished part.

One of the most effective ways to reduce costs is by consolidating features. When you combine multiple parts into a single component, you minimize assembly steps and improve structural strength. This approach also reduces the number of setups required on the machine, which lowers programming and labor expenses.

Standardization plays a key role in cost-effective cnc machining. By using standard sizes, hole diameters, and thread types, you simplify tool selection and reduce the need for custom tooling. Standard features allow the machine to operate at optimal speeds, which shortens cycle times and increases throughput.

Tolerances directly affect both machining time and cost. You should avoid specifying unnecessarily tight tolerances unless your application demands it. The machine must slow down and use specialized tools to achieve extreme precision, which increases both setup and inspection time. For most applications, following ISO 2768 or ASME Y14.5 standards ensures reliable performance without excessive cost.

Tip: Always communicate your functional requirements clearly. This helps your cnc provider recommend the most efficient machining strategy.

The impact of order quantity on cost per unit is significant. The table below shows how increasing your batch size spreads setup costs across more parts, reducing the price for each unit:

Quantity | Setup Cost | Total Cost | Cost per Unit |

|---|---|---|---|

1 | $262.50 | $300 | $300 |

10 | $300 | $500 | $50 |

You see that higher quantities make cnc machining more economical. The initial setup cost for the machine remains almost the same, but producing more parts lowers the average cost per piece.

Here are some practical strategies for cost-effective cnc design:

Consolidate features to reduce part count and assembly.

Use standard dimensions and features to minimize custom tooling.

Specify only the tolerances you truly need.

Design parts for easy fixturing and minimal repositioning on the machine.

Avoid deep cavities and thin walls, which require slower machining and special tools.

Select materials that balance performance with machinability.

By applying these principles, you help your cnc provider deliver high-quality parts at a lower cost. You also shorten lead times and improve overall project efficiency.

Selecting the right cnc provider is a critical step in your machining project. You want a partner who understands your needs and delivers reliable results. The right provider helps you achieve precision, efficiency, and quality in every part you order.

When you evaluate a cnc provider, focus on these essential criteria:

Technical Capabilities: Check if the provider has the right machine types for your project. Multi-axis machines, turning centers, and milling machines should match your part requirements.

Quality Standards: Look for certifications such as ISO 9001 or compliance with ISO 2768. These standards show a commitment to quality in machining.

Experience and Track Record: Providers with years of experience in cnc machining often deliver better results. Ask about their work with similar industries or parts.

Material Expertise: Make sure the provider can machine the materials you need, whether metals, plastics, or composites.

Inspection and Tolerance Control: Reliable providers use advanced inspection tools and follow strict tolerance guidelines. This ensures your parts meet specifications.

Production Capacity: Confirm the provider can handle your order volume, from prototyping to full production runs.

Lead Time and Delivery: Fast turnaround and on-time delivery are important for your schedule.

Tip: Review sample parts or case studies to see the provider’s machining quality and machine capabilities.

Before you choose a cnc provider, ask these key questions:

What types of machine do you use for cnc machining?

Can you meet my required tolerances and surface finishes?

How do you ensure quality control during and after machining?

What is your typical lead time for similar projects?

Do you offer support for design optimization or material selection?

How do you handle urgent orders or changes in production volume?

What industries have you served with your cnc machine services?

Can you provide references or examples of past machining projects?

What is your process for quoting and communication?

How do you manage machine maintenance and minimize downtime?

These questions help you understand the provider’s strengths and reliability.

Watch for warning signs that may indicate a cnc provider is not the right fit:

Lack of clear communication or slow response times.

No evidence of machine maintenance or quality certifications.

Limited machine types or outdated equipment.

Inability to provide references or examples of previous machining work.

Unclear pricing or hidden fees.

Poor documentation of inspection and tolerance control.

Missed deadlines or inconsistent delivery.

Note: A trustworthy cnc provider invests in modern machine technology, follows industry standards, and values transparent communication.

Choosing the right partner ensures your machining project runs smoothly and meets your expectations for quality and precision.

You begin your cnc journey by preparing digital files for your project. Most cnc machining providers require a 3D CAD file, such as STEP or IGES format. This file contains all the geometric details your machine needs to create the part. You should include clear dimensions, tolerances, and surface finish requirements. If you have special features, such as threads or engraved text, mark them in your design. You help your provider by supplying a drawing with notes for critical areas. Well-prepared files reduce errors and speed up the machining process.

Tip: Use standard file formats and double-check your dimensions before submitting. This step ensures your machine interprets the design correctly.

You request a quote by sending your files and project details to a cnc machining service. Providers need information about material type, quantity, tolerances, and any finishing requirements. You should specify your expected lead time and delivery location. Many companies offer online quote forms for convenience. Minimum order quantity is a common concern. Some providers accept single prototypes, while others require batch orders. Shipping options also affect your decision. You can choose express delivery for urgent projects or standard shipping for cost savings.

| Quote Requirement | Description | Why It Matters |

| CAD File | 3D model with dimensions | Guides the machine |

| Material | Aluminum, steel, plastics | Impacts machining cost |

| Quantity | Number of parts | Affects price per unit |

| Tolerances | Precision needed | Determines machine setup |

| Surface Finish | Polished, matte, anodized | Impacts post-machining steps |

| Lead Time | Delivery date | Schedules machine availability |

| Shipping | Express, standard | Influences total cost |

You start with prototyping to test your design before full production. CNC machining allows you to create one-off prototypes with the same machine used for mass production. You evaluate fit, function, and appearance. If changes are needed, you update your CAD file and repeat the process. Once you approve the prototype, you move to production. The machine uses the same program to produce consistent parts at scale. You monitor quality and inspect samples to ensure every part meets your standards.

Prototyping helps you validate your design and avoid costly mistakes.

Production uses automated machines for repeatable results.

You can order small batches or large volumes based on your needs.

Tip: Discuss minimum order quantity and shipping options with your provider to optimize cost and delivery.

You streamline your cnc machining project by preparing files carefully, requesting accurate quotes, and using prototyping to refine your design. For expert support and reliable service, reference cnkaierwo.com as a trusted resource.

You have seen how cnc machining delivers precision, flexibility, and efficiency for your projects. When you use a cnc machine, you gain control over every detail, from design to finished part. Each machine supports a wide range of materials and applications. You can trust cnc machining for both prototyping and production. Every machine in your shop helps you meet strict standards and tight tolerances. If you have questions about cnc or want to optimize your next machining project, reach out to a cnc expert. Request a free cnc machining quote today and see how the right machine can transform your business.

You can order a single part or a large batch. Many cnc providers accept low-volume orders, making prototyping and small production runs easy. Always check with your chosen service for specific minimum requirements.

You should consider strength, weight, corrosion resistance, and cost. Discuss your application with your cnc provider. They can recommend materials like aluminum, steel, or plastics based on your needs and industry standards.

Most cnc machining services accept 3D CAD files such as STEP, IGES, or STL. You should include all dimensions, tolerances, and notes in your file. Clear files help the cnc process run smoothly and reduce errors.

Lead times depend on part complexity, material, and order size. Simple cnc parts may ship in days. Complex or high-volume orders can take several weeks. Communicate your deadlines early to ensure timely delivery.

Yes, you can request various surface finishes, including anodizing, polishing, or powder coating. Surface finishing improves appearance and performance. Specify your requirements when you submit your cnc order.

You should follow design for manufacturability guidelines. Use standard features, avoid deep cavities, and specify only necessary tolerances. Consult your cnc provider for feedback on your design before production.

You find cnc machining in aerospace, automotive, medical devices, electronics, and industrial equipment. These industries rely on cnc for precision, repeatability, and the ability to produce complex parts from many materials.

Contact Us

Rapid Prototyping CNC LIST

Advantages of CNC TurningApplications of Vacuum CastingRapid Tooling Service CompanyPrototype Manufacturing Technologies & Tools: A Complete GuideAluminum CNC Machining: High-Precision Aluminum CNC ServicesComplete Guide to 3D Printing MaterialsInjection Molding Manufacturing ServicesCheap CNC Milling ServicesHow to Prevent Surface Oxidation in Aluminum CNC MachiningFrom Design to Delivery: How Low Volume Manufacturing Accelerates CustomizationAluminum CNC Machining Standard Hole SizesCNC Milling Service CompanyHow to ensure your rapid prototype meets the final product specificationsCNC Machining Aluminum and Plastic ServicesComprehensive Guide to Kaierwo Vacuum Casting ServicesCost Analysis: CNC Machining vs. 3D Printing in Medical ApplicationsComprehensive Aluminum Processing FAQVacuum Casting Materials Guide5 Axis Precision Machining ServiceAluminum CNC Machining Quotation GuideCNC machining materialsSheet Metal Fabrication Services|KaierwoThe Role of 3D Printing in Personalized Healthcare SolutionsA Complete Guide to CNC Design: Best Practices for Engineers, Designers, and Purchasers3D Printing Industry GlossaryFDM (Fused Deposition Modeling) 3D PrintingA Complete Guide to CNC Machining5 Axis Machining Services|KaierwoCNC Machine Shop Precautions: A Practitioner’s Best-Practice PlaybookOne-Stop Aluminum CNC Machining: From Rapid Prototype to Small-Batch Electronics EnclosuresHow to Reduce Time-to-Market for Medical Devices with Rapid PrototypingHow companies use rapid prototyping to shorten development timePlastic Prototyping Methods: Processes, Materials, Tolerances, and DFM TipsComprehensive Guide to 3D Printing Surface Finishing Methods3D Printing Die Casting: Revolutionizing Manufacturing ProcessesRapid Prototyping Industry Glossary: Key Manufacturing Terms ExplainedCNC Machining for Rapid Prototyping Design TechniquesTop 10 Factors to Consider When Selecting a Plastic Injection Molding Service ProviderIndustries That Use Aluminum CNC Machining3D Printing Service FAQsFrom CAD to Reality: How Rapid Prototyping with Additive Manufacturing WorksCNC Machining Applications Across IndustriesPlastic Injection Mold Making and Custom Casting MoldsHow to Validate a Medical Prototype Before Production?Aluminum surface finishing for corrosion resistance