We attach great importance to customers' needs for product quality and rapid production.

We always insist that meeting customers' needs is to realize our value!

+86 133 9281 9446

Consumer electronics products demand high precision, refined appearance, and fast product iteration.

At Kaierwo, we support consumer electronics companies with reliable CNC machining and rapid manufacturing solutions — from early prototypes to functional testing and low-volume production.

With strong engineering support and strict quality control, we help turn innovative electronic designs into market-ready products efficiently.

Aluminum

Lightweight, strong, and highly machinable. Aluminum is widely used for electronic housings, frames, heat sinks, and structural parts that require both strength and premium surface finish.

Stainless Steel

Offers higher strength and wear resistance. Commonly used for internal frames, brackets, connectors, and parts exposed to repeated mechanical stress.

Copper & Brass

Excellent thermal and electrical conductivity. Ideal for heat dissipation components, shielding parts, and electrical connectors.

ABS

Cost-effective plastic with good strength and surface quality. Frequently used for device housings, covers, buttons, and internal structural parts.

PC (Polycarbonate)

High impact resistance with good transparency. Suitable for protective covers, transparent parts, and electronic enclosures.

PC+ABS balanced material combining toughness, heat resistance, and surface quality. Widely used for consumer electronics housings.

POM (Delrin)

Rigid, low-friction engineering plastic. Often applied to precision components such as buttons, sliders, connectors, and small mechanical parts.

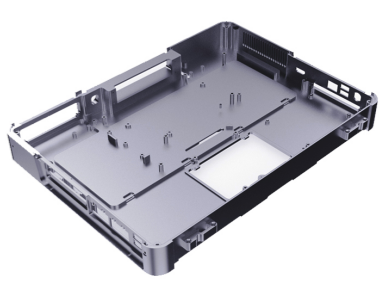

CNC Machining (Metal & Plastic)

Precision machining for electronic housings, frames, heat sinks, and internal components.

Ideal for producing small batches of high-quality plastic parts with production-like appearance.

Injection Molding & Rapid Tooling

Low-volume injection molding for enclosures and plastic components using rapid molds.

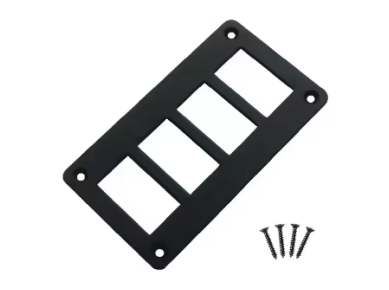

Thin metal parts for brackets, internal frames, and electronic enclosures.

Surface Finishing & Assembly Support

Anodizing, polishing, painting, and cosmetic treatments for consumer-facing products.

Electronic housings and enclosures

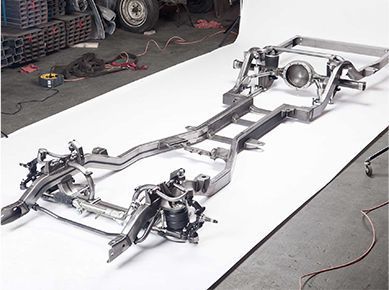

Structural frames and internal brackets

Heat sinks and thermal management parts

Buttons, connectors, and mechanical interfaces

Wearable device components

Smart home and IoT product parts

Why Choose Kaierwo For Consumer Electronics Manufacturing?

1.Engineering-Driven Manufacturing

Our experienced engineering team works closely with your designers and product engineers to review part structures, tolerances, and material selection. We help optimize designs for manufacturability, ensuring reliable performance, cost efficiency, and smooth transition from prototype to production.

2.Fast Prototyping & Iteration

Consumer electronics development moves fast. Kaierwo provides rapid prototyping and quick-turn CNC machining to support frequent design iterations, functional testing, and market validation—helping you shorten development cycles and stay ahead of competition.

3.Wide Material Capability

We machine a broad range of metals and engineering plastics commonly used in consumer electronics, including aluminum, stainless steel, copper, ABS, PC, PC+ABS, and POM. Our team supports material selection based on strength, appearance, thermal performance, and budget requirements.

4.Stable Quality & Repeatability

With standardized machining processes and strict quality inspection, we ensure consistent dimensional accuracy and surface quality across every batch. Our repeatable manufacturing capability helps maintain product reliability from early samples to low-volume production.

Reviews

Product Development Engineer, Consumer Electronics Company

“Kaierwo supported us with CNC machining for our consumer electronics housing and internal structural parts. The dimensional accuracy and surface finish met our expectations, and their engineering feedback helped us optimize the design for production. Communication was clear and turnaround was fast.”

Hardware Engineering Manager, Smart Electronics Brand

“We worked with Kaierwo on multiple prototype iterations for a smart device project. They were responsive, flexible with design changes, and delivered consistent quality across samples. Kaierwo has become a reliable manufacturing partner for our electronics development.”

Certifications

We use advanced metrology equipment to verify all incoming raw materials and will provide you full certificates of compliance for your peace of mind. Our metrology equipment includes Roughness, Vernier calipertester, Micrometer, etc. More information about our enquipment please read our page Quality Inspection. Our facility is fully certified to ISO13485:2016, ISO9001:2015, etc

1.OUR FACTORY VIDEO

More Industries we work with

Medical Devices

Transprent parts

Aluminum parts

We attach great importance to customers' needs for product quality and rapid production.

We always insist that meeting customers' needs is to realize our value!