We attach great importance to customers' needs for product quality and rapid production.

We always insist that meeting customers' needs is to realize our value!

+86 133 9281 9446

Dec. 26, 2025

Leo Lin.

I graduated from Jiangxi University of Science and Technology, majoring in Mechanical Manufacturing Automation.

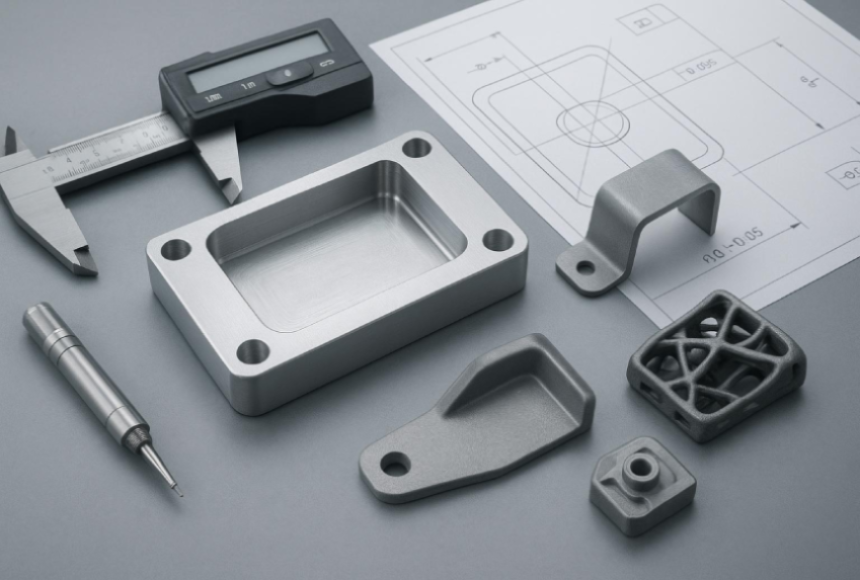

Selecting the right metal prototyping route determines how quickly you validate fit, function, and finish—and how smoothly you scale from a one-off to pilot runs and production. This guide compares core methods side-by-side and gives you the practical rules engineers rely on: realistic tolerances, surface finish ranges, DFM guardrails, QA/inspection checkpoints, and how finishing impacts dimensions.

Match process to requirement: tight tolerances and smooth surfaces favor CNC; fast complexity with internal channels often leans to SLM/DMLS; brackets and enclosures excel in sheet metal; bridge runs with casting require draft and tooling lead time.

Specify only critical tight tolerances; default the rest to ISO 2768 classes and use GD&T (ASME Y14.5) for functional relationships. Tightening everything raises cost and risk without improving function.

Finishing changes dimensions. Anodizing, plating, and powder coating add thickness; bead blasting changes Ra. Call out critical post-finish dimensions and inspection methods.

Plan prototype-to-production early: confirm materials available at scale, validate bend radii, draft, wall thickness, and inspection plans before locking the design.

Below is a compact decision matrix you can use as a first pass. It’s a guide, not a rulebook—confirm with your manufacturing partner.

| Requirement/Constraint | CNC | Sheet metal | SLM/DMLS metal AM | Die/investment casting |

|---|---|---|---|---|

| Geometry complexity (internal channels, lattices) | Moderate; 5-axis helps | Low–moderate (2.5D folds) | Very high (freeform, internal) | Moderate–high (depends on tooling, gates) |

| Typical tolerances | ±0.005 in (±0.127 mm) general; tighter on critical | ±0.2–0.5 mm overall; bends ±1° typical | ±0.1–0.3 mm typical; post-CNC to tighten | Investment: per ISO 8062 grade; die cast: tight on datums |

| Surface as-built | Ra 1.6–3.2 µm typical | Tooling marks, Ra varies | Ra ~6–13 µm; rougher; needs finishing | As-cast Ra varies; machining on critical faces |

| Lead time | Fast for 1–10 pcs | Very fast for brackets/enclosures | Fast for complex parts; post-proc adds time | Longer (tooling) unless rapid tooling used |

| Volume sweet spot | 1–100+; scales with setups | 1–500+ with standard gauges | 1–50+ (functional prototypes) | 100s–100k+ (after tooling) |

| Cost drivers | Setups, tool access, 5-axis | Bends/number of ops, tolerances | Supports, post-machining, orientation | Tooling cost, draft, parting lines |

CNC is the most versatile route for functional parts where tolerance and surface finish matter. As a baseline, many shops hold around ±0.005 in (±0.127 mm) on metals, with tighter control on critical features—reamed bores or ground surfaces can reach ±0.0005–0.001 in (±0.0127–0.025 mm) under the right setups. Industry summaries align with this range, and you can see tolerance strategies discussed in sources like Protolabs and Fractory; as a general design approach, use ISO 2768 general tolerances for non-critical dimensions and reserve tight GD&T callouts only for features that affect function, as outlined in the public summary of ISO 2768 from RP Proto in 2021: see the General Tolerances table in the RP Proto PDF: General Tolerances ISO 2768 (RP Proto, 2021).

Surface finish right off the machine is frequently Ra 63–125 µin (1.6–3.2 µm). If you need a “consumer-grade” appearance, specify bead blasting before anodize on aluminum, or polishing/electropolishing for steels; remember that secondary finishing can slightly alter dimensions and burr conditions.

DFM guidance that prevents rework is straightforward. Maintain minimum wall thicknesses relative to material and end mill reach; avoid deep, narrow slots that require micro-tools; design fillets to match standard cutter radii (e.g., 1, 2, 3 mm) unless a sharp corner is functionally necessary; and prefer through-holes over deep blind holes to ease chip evacuation. For complex geometries, 5-axis machining reduces setups and improves accuracy on multi-sided parts; if you’re comparing options, browsing an overview like 5-axis machining service can help you understand when simultaneous motion pays off.

When you need a vendor perspective, see a neutral service overview such as CNC machining services, then map your drawing’s CTQs (critical-to-quality) to the supplier’s stated capabilities. For aluminum housings or heat sinks, it’s often helpful to cross-check alloy-specific pages like Aluminum CNC machining services to align finishing and temper selections with what’s available quickly.

For the language of tolerances and datums, the ASME Y14.5 standard remains the reference in many markets. ASME’s page provides the official scope and resources: see ASME Y14.5 – Geometric Dimensioning and Tolerancing (ASME, access page).

Sheet metal shines for brackets, chassis, and enclosures. Bends introduce unique constraints you should encode in your drawings or flat patterns. As a rule of thumb, minimum inside bend radius is about 1×T for many ductile alloys; harder tempers (e.g., 6061‑T6) may need 1.5–3×T to avoid cracking. Keep minimum flange length at ≥4×T so the punch and die can form the bend without distortion. Maintain hole edges at least 2×T away from bend lines to reduce tear-out and ovalization, and avoid tiny holes near bends that cannot be supported by tooling.

Because forming stretches material, you’ll typically see bend angle tolerances around ±1°, with overall dimensions falling under general tolerancing such as ISO 2768 unless otherwise specified. A handy way to sanity-check design limits is with a publicly available calculator or table; for example, see a bend radius table like Xometry’s reference calculators, or detailed DFM PDFs such as Fictiv’s 2024 guide for context on minimums and K-factor ranges. For a service perspective and practical notes on gauge availability, compare your requirements with a provider overview like Custom sheet metal fabrication service.

Surface considerations matter here too. Grain direction can telegraph on brushed finishes, laser-cut edges can have slight striations, and bead blasting can even out cosmetic inconsistencies before anodizing or powder coating. Always state whether hole sizes are measured before or after finishing, and whether threads are masked.

Laser powder bed fusion (LPBF), often called SLM or DMLS, enables internal channels, conformal cooling, lattices, and weight-optimized forms that machining cannot reach. Design within machine and material boundaries and plan for post-processing.

OEM data sheets and reputable guides provide practical starting limits. EOS lists for common alloys like StainlessSteel 316L and AlSi10Mg minimum wall values around 0.3–0.4 mm depending on parameters and orientation; see the data sheet for 316L here: EOS StainlessSteel 316L Material Data Sheet (EOS, latest available). For unsupported overhangs, a conservative rule is to avoid features shallower than ~45° to the build plate unless you’re prepared for supports and the post-processing to remove them; Renishaw summarizes these beginner rules in its primer: Design for metal AM — a beginner’s guide (Renishaw).

Expect as-built surface roughness in the ~6–13 µm Ra range depending on alloy, layer thickness, and orientation. Functional faces usually need machining, grinding, or other finishing after printing to meet tight tolerances and surface requirements. It’s common to add machining stock on pads and bores and to align those features with fixturing datum strategies.

When comparing SLM/DMLS with CNC for a metal prototype, ask: Do internal channels or weight-driven topology changes deliver value? If yes, AM may win—even if you need a secondary CNC pass—to reduce part count or enable performance. If the geometry is primarily prismatic with tight fits and cosmetic expectations, CNC often remains faster and more economical. For blended routes, some teams print near-net shapes and then finish-machine CTQs.

Finishes close the loop between functional performance, corrosion resistance, appearance, and touch. They also alter dimensions. Always state whether dimensions apply before or after finish and define masking, thread protection, and critical datum faces.

Typical thickness ranges are well-documented in design tips and standards:

Anodizing (aluminum): Type II around 5–25 µm; Type III hard anodize 25–150 µm, with roughly half the thickness growing inward and half outward. Protolabs summarizes design considerations in its finishing note: Plating and finishing considerations for CNC and sheet metal (Protolabs).

Electroless nickel and chrome systems: Electroless nickel typically 12–38 µm; decorative chrome stacks ~0.3–2 µm over a 5–15 µm nickel layer; hard chrome can run 10–500 µm depending on application. For process parameters and system choices, the Nickel Institute’s reference is useful: Nickel Plating Handbook (Nickel Institute, 2023). ISO 1456 provides classification for nickel/chromium decorative coatings and is often cited in specifications; reference copies and summaries are available online from standards repositories.

Powder coating: 50–125 µm is common for electrostatic spray; fluidized bed processes can exceed 100–500 µm.

Surface roughness evolves with finish. Bead blasting tends to produce a matte Ra around ~1.6–3.2 µm; polishing and electropolishing can push Ra below 1 µm, even down to ~0.1 µm on some stainless steels. If sealing or sliding is involved, call out Ra/Rz per ISO 4287/4288 and specify how it’s measured (contact profilometer vs optical).

Inspection plans protect budgets and schedules. Start with a drawing that combines: material specs and temper, heat treatment where applicable, finish callouts with thickness and masking, general tolerances (e.g., ISO 2768-mK) for non-critical dimensions, and GD&T for functional relationships (datums, true position, flatness, perpendicularity). If you’re syncing with North American suppliers, the standard reference is ASME Y14.5; see the official access page: ASME Y14.5 — Geometric Dimensioning and Tolerancing. For default manufacturing tolerances when values aren’t explicitly stated, see a summary of ISO 2768 general tolerances (RP Proto PDF).

Plan your methods by feature and finish:

Dimensional CTQs and GD&T features: CMM measurement in a temperature-controlled room, with measurement strategy aligned to datums.

Surface roughness: Ra/Rz validation after finishing on sealing faces or sliding features.

Hardness and case depth (if heat-treated or plated): Rockwell/Vickers and thickness checks.

NDT (as needed): Liquid penetrant for surface-breaking cracks, ultrasonic for internal defects, and radiography/CT for casting integrity in critical parts.

Pro tip: state whether acceptance occurs pre- or post-finish and whether any functional dimensions are “after finish” dimensions; otherwise, you risk unplanned rework.

Quality credentials and equipment. Our QMS is certified to ISO 9001:2015 and ISO 13485:2016.

The shortest path from prototype to production is to design like production from the start. That doesn’t mean expensive tooling on day one; it means encoding the rules that downstream processes require.

Three themes keep teams out of trouble. First, align tolerances to capability: use ISO 2768 defaults for most features, tighten only where function requires it, and use GD&T to control relationships. Second, standardize materials and finishes that will be available at scale; pick alloys and coatings your supply chain can source quickly in the volumes you expect. Third, validate manufacturability on the intended process early—bend radii, minimum walls, draft, and tool access—so your prototype doesn’t pass tests you can’t reproduce at volume.

If you’re comparing routes or need quick feasibility checks across multiple processes, an overview page like Rapid prototyping helps you translate requirements into process choices. As your design stabilizes, shift conversations to Mass production criteria: tooling strategies, pilot runs, and process capability (Cp/Cpk) targets on CTQs. Think of pilot runs as your dress rehearsal for quality documentation and logistics.

| Topic | Typical range | Notes/Standards |

|---|---|---|

| CNC general tolerance (metals) | ±0.005 in (±0.127 mm) | Tighten to ±0.002 in (±0.051 mm) selectively; bores post-ream/ground to ±0.0005–0.001 in |

| CNC as-machined roughness | Ra 1.6–3.2 µm (63–125 µin) | Improve via bead blast, polish, grind |

| Sheet metal bend angle | ±1° typical | Minimum inside radius ≈ ≥1×T (material/temper dependent) |

| SLM/DMLS min wall | ~0.3–0.4 mm | OEM- and orientation-dependent (see EOS material data) |

| SLM/DMLS as-built Ra | ~6–13 µm | Post-process to meet CTQs |

| Die casting draft | ~1.5–2° | Add more for textures; see NADCA design guides |

| Investment casting wall | ~0.8–2.5 mm | Tolerances per ISO 8062 grade |

| Anodize thickness | Type II 5–25 µm; Type III 25–150 µm | Dimensional growth ~half inward/half outward |

| Electroless nickel | 12–38 µm | Beware bore buildup; mask as needed |

| Powder coat | 50–125 µm (spray) | Fluidized bed can exceed 100–500 µm |

Are my tight tolerances limited to CTQs, with ISO 2768 on the rest, and GD&T capturing fit/function?

Do I understand how finishing changes dimensions, and did I call out “after finish” measurements on critical features?

Does my process choice reflect geometry reality—tool access and bend radii for CNC/sheet metal, draft for casting, supports and stock for SLM/DMLS?

ISO 2768 general tolerances (public summary): General Tolerances ISO 2768 — RP Proto PDF (2021)

GD&T standard overview: ASME Y14.5 — Dimensioning and Tolerancing (ASME access page)

Metal AM design limits: EOS StainlessSteel 316L Material Data Sheet and Renishaw — Design for metal AM (beginner’s guide)

Casting design: Die Casting Product Design — NADCA (PDF) and Investment casting guide — Investacast

Finishing: Plating and finishing considerations for CNC and sheet metal — Protolabs and Nickel Plating Handbook — Nickel Institute (2023)

We attach great importance to customers' needs for product quality and rapid production.

We always insist that meeting customers' needs is to realize our value!