We attach great importance to customers' needs for product quality and rapid production.

We always insist that meeting customers' needs is to realize our value!

+86 133 9281 9446

Sep. 25, 2025

Leo Lin.

I graduated from Jiangxi University of Science and Technology, majoring in Mechanical Manufacturing Automation.

You can see CNC machining is changing how cars are made. CNC gives car makers more speed, better accuracy, and new ways to build cars. Kaierwo is a leader in Automotive Prototyping and Parts Manufacturing. They use advanced methods and follow strict rules. This means you get parts you can trust that meet hard standards.

The car making industry uses about 20% of all CNC machines in the U.S.

By 2025, car and transportation companies will have 28.3% of the world’s CNC machine market.

The car industry thinks it will grow by almost 12.0% each year.

CNC helps suppliers and makers build better cars more quickly.

You want your car parts fast and dependable. CNC makes the process much quicker. It helps save time and makes fewer mistakes. With cnc, you do not need to set up machines as often. This means you get your parts sooner. For example, 5-axis cnc machining can make hard parts in less steps. You get your prototypes and finished parts faster.

Here is how cnc machining helps make car parts faster:

Strategy | Description |

|---|---|

Minimize Setups | Fewer setups save time on each part and speed up work. |

Standardize Designs | Using the same tools and materials makes changes easier and quicker. |

Advanced Technologies | Smart cnc machines with IoT and AI work longer and waste less. |

CNC helps you during the prototyping stage too. You can change designs and test ideas quickly. You do not have to wait weeks for new parts. When your design is ready, cnc can make many parts fast. This keeps things efficient from start to finish.

Every car part must fit and work just right. CNC gives you the accuracy needed for today’s cars. CNC machining can make parts with very tight tolerances. This keeps your parts the same and dependable.

Here are some common tolerances you get with cnc machining:

Tolerance Type | Tolerance Value | Application Description |

|---|---|---|

Standard Tolerance | ±0.005 in. (0.13 mm) | Prototypes, general parts, and non-critical features |

High Precision | ±0.002 in. (0.051 mm) | Tight fits and important features needing accuracy |

Reamed Holes | ±0.0005 in. (0.0127 mm) | Precision fits like pins, shafts, or press-fit parts |

You can count on cnc to make parts that meet tough car industry rules. This level of accuracy is extra important for electric cars. Every part must work its best.

CNC helps car makers try new ideas and designs. You can make new parts, test them, and build advanced cars like electric vehicles. CNC machining makes parts for motors, battery cases, and cooling systems. You can change designs fast and keep up with new trends.

Here are some ways cnc helps car makers be creative:

You can change and customize parts quickly.

Smart software and IoT sensors make production flexible.

CNC machining cuts down on waste and saves energy, helping electric cars be greener.

Kaierwo uses the newest cnc technology and software. Their team helps you turn ideas into real parts. With their skills and equipment, you can try new things in car design.

When you look at a car, you see many parts. These parts work together to make the car run. Kaierwo helps you get the right parts for each system. You can pick metals like aluminum, stainless steel, titanium, or carbon steel. You can also choose hard plastics. Kaierwo can make enclosures and strong fittings for your needs.

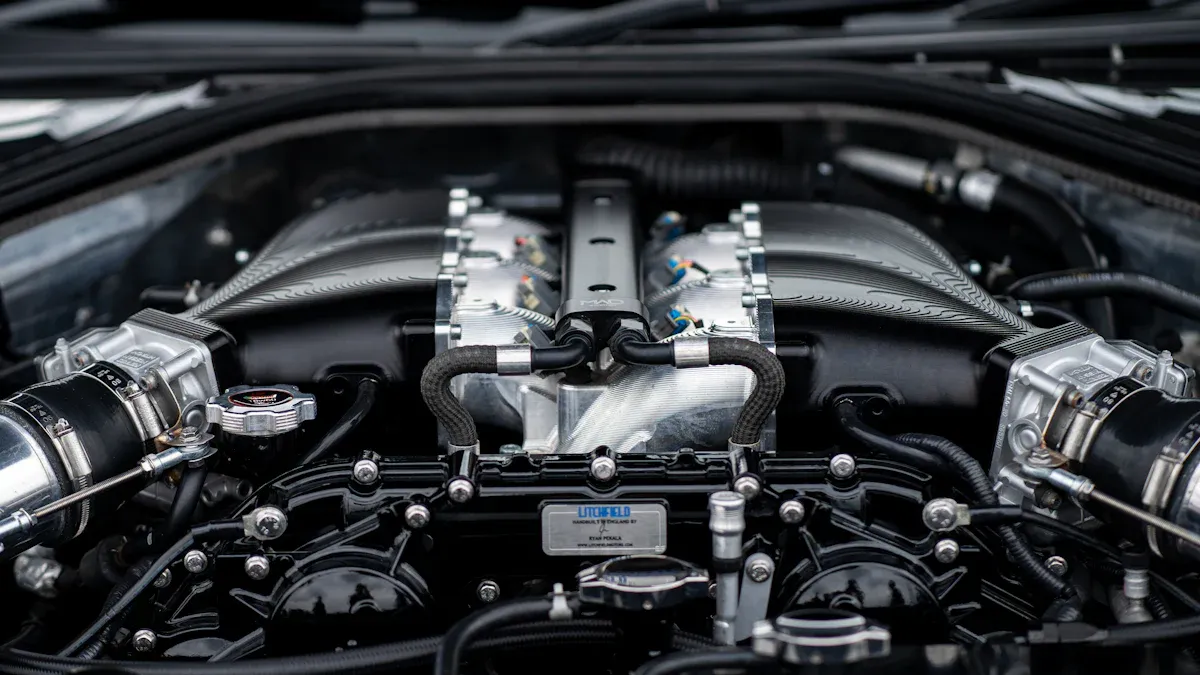

The engine is the heart of your car. You need engine parts that last a long time. They must work well every day. Kaierwo uses CNC machining to make parts with tight fits. You get cylinder heads, crankshafts, camshafts, pistons, and valves. These parts fit just right. They help your engine run smooth and use less fuel. Kaierwo’s machines make sure every part meets strict rules.

Suspension makes your ride smooth and safe. You want parts that handle bumps and sharp turns. Kaierwo makes suspension parts from strong materials:

Stainless steel does not rust and bends without breaking.

Aluminum is light but strong.

Titanium is tough and does not wear out fast.

Carbon steel is easy to shape and stays strong.

Thermoplastics bend and last a long time.

Transmission sends power from the engine to the wheels. You need parts that work with high accuracy. Kaierwo uses CNC machining to make gears, driveshafts, and more. You get parts that match each other and fit well. Steel alloys are strong and do not break easily. Aluminum is light and helps save weight. Special coatings like anodizing and heat treating make parts last longer. Every transmission part must be exact for good performance.

CNC machining makes parts more reliable.

Hardened steel gears can take heavy loads.

Smooth finishes help parts last longer.

Brake systems keep you safe on the road. You need parts that meet safety rules. Kaierwo follows rules like ANSI B11.3-2022 for safety. CNC machining makes brake parts that stop your car fast and safely. You get parts for calipers, rotors, and brackets.

Brake System Part | Function | Material Options |

|---|---|---|

Caliper | Holds brake pads | Aluminum, Steel |

Rotor | Makes friction | Cast Iron, Steel |

Bracket | Holds parts together | Steel, Aluminum |

You can trust Kaierwo for parts that keep your car safe and running well.

Kaierwo gives you everything you need for car part making. You can go from your design to finished parts without changing suppliers. This saves you time and money. You get choices for making a few parts or testing new ideas. Kaierwo offers CNC machining, sheet metal work, vacuum casting, and rapid tooling. Each way helps your car project in a special way.

CNC machining is important for making car prototypes and parts. You get very exact parts, quick results, and save money. CNC machines use metals and plastics. They make shapes that old methods cannot do. You can make test parts fast and change designs easily.

Advantage | Description |

|---|---|

Precision | CNC machining gives you exact parts and fewer mistakes. |

Speed | CNC machines work faster than people and save time. |

Cost-effectiveness | Less work and less wasted material means you spend less. |

Complex geometries | CNC machines make hard shapes that old ways cannot do. |

Automation helps lower work costs and keeps machines working longer. CNC machining lets you try new ideas fast. You can change things and see results quickly. This helps you stay ahead in car making.

Sheet metal work makes strong and light car parts. You use it for covers, brackets, and body pieces. Kaierwo uses the same materials for testing as for final parts.

Benefit | Description |

|---|---|

Fast Turnaround for Product Development | Quick testing helps you find and fix problems fast. |

Cost-Effective for Low-Volume Production | You do not need expensive tools, so small batches cost less. |

Use of Planned Production Materials | You test with real materials to make sure parts work right. |

High Accuracy and Repeatability | You get exact and repeatable results for good testing. |

You get parts that match the final ones. This helps you test and check designs with trust.

Vacuum casting helps you make good test parts fast. You get smooth parts with no bubbles. This is great for dashboards, covers, and parts that need to look nice.

Vacuum casting makes parts quickly and keeps them high quality.

You can turn computer designs into real parts fast.

You test fit and look before making lots of parts.

You can check how parts work without spending much on tools.

Engineers use vacuum casting to see how parts fit and look. You can change things before making many parts. This saves you time and money.

Rapid tooling helps you go from test parts to real parts fast. You make molds quickly with new ways like 3D printing and CNC machining. This helps you test new car parts faster.

Rapid tooling makes it easy to make and test new parts. You can sell new models fast and spend less than old ways. You get working test parts to find problems early. This helps you move from ideas to making lots of parts and saves money.

Tip: Rapid tooling helps you keep up with changes and what customers want.

Kaierwo’s one-stop service lets you pick the best way for your car project. You can test ideas, change things, and make lots of parts with trust. This helps you be creative and make good car parts.

CNC automation is changing how tools are handled in car making. Robots and rotary tables switch tools fast. The machine does not need to stop for tool changes. This makes production faster and reduces waiting time. Automatic tool changers work best when making many parts. You do not have to stop for manual tool changes. This keeps your work going and helps you fill big orders. Automation also makes each part match the same rules. Every part comes out the same. You get good quality every time.

Tip: CNC automation helps your line keep moving and makes parts accurate.

Automation makes moving materials easier in car factories. Robots and conveyors carry raw materials and finished parts. You do not have to lift heavy things by hand. This lowers mistakes and keeps workers safe. CNC automation tracks where materials go. It sends them to the right place. You get better work speed and less waste. Automated systems sort, load, and unload parts the same way each time. You can trust that every part is handled right. This keeps your process smooth and your results steady.

Automated material handling saves you time.

You lower mistakes and injuries.

You get better repeatability and product quality.

CNC automation uses special production cells to help make cars. These cells use machines, robots, and software together. You can set them up for different parts and amounts. You can change settings quickly when needed. This helps you make more or fewer parts as needed. Automated cells cut down on waiting and make work faster. You get better quality and can react to changes fast.

Benefit | Description |

|---|---|

Fast Programming | Automation lets you switch tasks quickly. |

Real-time Adjustments | You can change settings fast to meet new needs. |

Increased Scalability | Automated cells help you make more parts and fill big orders. |

Reduced Downtime | Automation keeps machines working with fewer stops. |

Improved Product Quality | You get the same results every time with cnc automation. |

CNC machining with automation gives you ways to grow your business. You can handle new problems and keep your customers happy.

You want results fast in car making. CNC machining works quickly. Machines run all day and night. You get parts faster than old ways. This helps you test new ideas sooner. You can bring cars to market faster. If you need drive units for electric vehicles, CNC machining helps you go from design to production quickly. You do not wait long. You can follow trends and stay ahead of others.

Saving money is important in car making. CNC machining helps you spend less in many ways:

You can choose cheaper materials for small orders.

Fewer finishes mean you spend less on each part.

Using the right blank size means less waste.

Making more parts at once lowers the cost for each part.

Simple shapes make machining easier and cheaper.

CNC machining helps you avoid mistakes that cost more later. You get the right parts the first time. This keeps your budget safe.

You need special parts for new cars or models. CNC machining lets you make custom designs with high accuracy. You can make parts for fast cars or special editions. This process helps you offer something different in car making. You do not wait for new tools or molds. You can change designs fast and meet what customers want.

Quality matters in car making. Kaierwo makes sure every part meets strict rules. They use advanced checks at every step. Here is how Kaierwo keeps quality high:

Quality Control Aspect | Description |

|---|---|

Certifications | ISO9001 2015 and ISO 13485 certified, showing they follow quality rules. |

Raw Materials Control | They check materials to meet client needs and have test certificates. |

Inspection Procedures | They inspect parts during and after making to check they are right. |

Comprehensive QC Team | Their team checks parts at many steps: FQC, IQC, IPQC, and OQC. |

Continuous Improvement | Staff can suggest ideas and find reasons for problems. |

CNC machining lowers errors and keeps parts the same. Machines use exact controls, so you get the same results each time. This is important for drive units and other key systems. You can trust Kaierwo to give you good quality and satisfaction every time.

CNC machining is changing how cars are made. It helps make cars faster. It makes parts more accurate and the same each time. It gives new ways to fix problems. Kaierwo gives good customer service and strong parts. They help with hard-to-make features and holding parts in place.

Trend | Impact on Automotive Industry |

|---|---|

Automation and Robotics | Machines work all the time and make more parts. |

Advanced Materials | New ways help use lighter materials in cars. |

Electric Vehicle Manufacturing | Making batteries and motors brings new problems to solve. |

Sustainability | Factories use less energy and help the environment. |

You can do these things to make your work better:

Get workers who know CNC well.

Teach your team about new CNC machines.

Use machines and checks to get good parts.

CNC machining uses computers to control machines that make car parts. These machines cut parts for engines, transmissions, and brakes. The parts are the right size and shape. This helps cars be safer and work better.

CNC machining gives you the same results every time. Machines follow set steps for each car part. This means fewer mistakes and better quality. You can trust the parts to meet tough car rules.

Yes, CNC machining lets you make special car parts. You can change designs fast. This helps you build new cars or test ideas. You get more choices for different car projects.

CNC machining makes battery cases, motor covers, and cooling parts for electric cars. These parts fit together well and work right. This helps new car technology and meets what the car industry needs.

You can pick metals like aluminum, steel, titanium, or plastics for car parts. CNC machining works with many materials. This gives you strong, light, or tough car parts.

We attach great importance to customers' needs for product quality and rapid production.

We always insist that meeting customers' needs is to realize our value!