We attach great importance to customers' needs for product quality and rapid production.

We always insist that meeting customers' needs is to realize our value!

+86 133 9281 9446

Aug. 25, 2025

Leo Lin.

I graduated from Jiangxi University of Science and Technology, majoring in Mechanical Manufacturing Automation.

You want fast, custom abs parts with great strength and quality. Kaierwo’s 3d printing service lets you get exactly that. Their fdm 3d printing and other advanced 3d printing methods give you reliable abs results. You can count on quick printing, expert support, and strict confidentiality. Kaierwo’s 98.7% on-time delivery rate and average response time of 2 hours or less show just how fast their 3d printing service works. When you need strong abs parts, their fdm 3d printing delivers quality every time.

Kaierwo’s 3D printing service makes strong ABS parts fast. You get custom parts with help from experts. Your information stays private and safe.

ABS material is strong and can handle heat well. It works for many things like car parts, toys, and models. This makes it good for lots of 3D printing jobs.

Kaierwo has easy steps and design tips to follow. You get good ABS parts quickly. Delivery is on time and finishing looks professional.

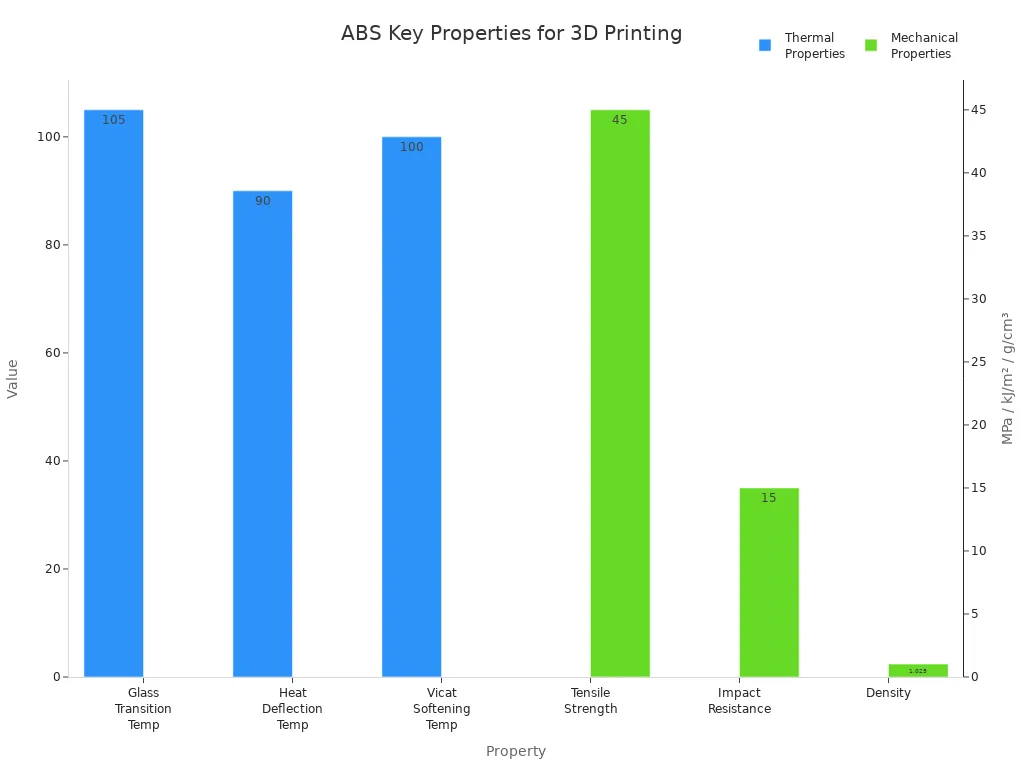

ABS is strong and reliable. It can handle heat up to about 105°C before it gets soft. The heat deflection temperature is between 80°C and 100°C. This means your 3d printed parts stay tough when it gets warm. ABS needs to be melted at 210°C to 250°C. The printer bed should be heated from 80°C to 100°C. This helps your 3d model stick and not warp. If you want more heat resistance, you can heat your part near 100°C for a short time. This is called annealing. ABS is tougher and lasts longer than many other materials. That is why people like it for fdm 3d printing.

ABS is used for many 3d projects. Car makers use it for dashboards, bumpers, and inside parts. People who build robots or electronics use it for cases and covers. It is also good for cosplay, toys, and sports gear. Even LEGO bricks are made from ABS. Its strength and heat resistance make it great for both factories and home use. You can use it for prototypes or finished products. ABS fits many 3d model needs.

Application Category | Examples of ABS 3D Printed Parts |

Industrial Applications | Prototyping, automotive parts, robotics, tooling |

| Consumer Applications | Toys, cosplay, sports equipment, home decor |

ABS has many good points for 3d printing.

It makes strong parts that do not break easily.

The high heat resistance lets your 3d model work in hot places.

You can sand, paint, or glue your 3d printed parts for a smooth finish.

ABS costs less than many other materials, so you save money.

With fdm, you can print tricky shapes fast and well.

It is strong and easy to work with, so it is good for testing and real products.

You get the same good results every time you print a 3d model.

ABS is a top choice for fdm 3d printing. It gives you strength, flexibility, and saves money for your 3d projects.

When you want custom ABS parts, you need a clear 3d printing workflow. Kaierwo makes this easy for you. Their 3d printing service uses a step-by-step process that helps you get the best results fast. Let’s walk through each stage so you know what to expect.

You start by sending your 3d model to Kaierwo. This is your first step in the 3d printing workflow. You upload your CAD file or 3d model through their secure system. Kaierwo’s team reviews your design to make sure it fits the 3d printing process. They do not offer design services, but they check your model for manufacturability. If they see any issues, they let you know right away.

Tip: Always double-check your 3d model before you submit. Make sure your file is complete and ready for 3d printing.

Kaierwo takes your privacy seriously during this stage. They protect your design with strict rules:

They sign and follow non-disclosure agreements if you ask.

No one takes photos of your 3d printed parts without your OK.

Kaierwo has handled thousands of unique designs for years and never leaked information.

You can trust Kaierwo to keep your 3d model safe. Their 3d printing workflow puts your confidentiality first.

After your design passes review, Kaierwo helps you pick the best 3d printing technology for your project. They look at your 3d model and your needs. Do you want strong, affordable parts? Fdm is a great choice. Need fine details or smooth surfaces? SLA might work better. For tough, functional parts, SLS is an option. If you want metal, SLM is available.

Kaierwo’s team explains the pros and cons of each 3d printing process. They help you match your model to the right technology. For most ABS parts, fdm 3d printing is the top pick. Fdm uses filament to build your 3d model layer by layer. This fused deposition modeling process is fast and cost-effective. You get strong, reliable parts for prototyping or end use.

Here’s a quick look at Kaierwo’s 3d printing technologies:

Technology | Best For | Materials | Surface Finish |

FDM | ABS, rapid prototyping, functional parts | ABS, PLA, PETG, more | Matte, can be smoothed |

SLA | Fine details, smooth models | Resin | Glossy, high detail |

SLS | Durable, complex shapes | Nylon, composites | Slightly rough, strong |

| SLM | Metal parts | Steel, titanium, alloys | Metallic, strong |

Kaierwo’s experts help you choose the right 3d printing workflow for your 3d model. They answer your questions and guide you through the process.

Once you pick your technology, Kaierwo starts the 3d printing process. Their team uses top machines and high-quality filament to print your 3d model. They monitor every step to make sure your parts meet your standards. After printing, they do post-processing like cleaning, sanding, or painting if needed.

Kaierwo’s 3d printing workflow includes strict quality checks. They hold ISO9001:2015 and ISO13485:2016 certifications. This means your 3d printed parts meet high standards every time.

You get your finished parts fast. Kaierwo’s average lead time for custom ABS parts is 7 to 14 days after you confirm your order. Even during busy times, you usually get your parts within 15 workdays. If your order is very complex, it might take longer, but Kaierwo always keeps you updated.

Kaierwo has years of experience in the 3d printing industry. Their team has worked with many clients and handled all kinds of 3d models. You get expert support at every stage. Their fdm printing service gives you strong, accurate parts for any need.

If you want a smooth 3d printing workflow, Kaierwo is ready to help. Their 3d printing service combines speed, quality, and confidentiality. You can trust them with your next 3d model or rapid prototyping project.

If you want strong and accurate parts, follow these rules.

Add a 45° chamfer or a rounded edge to the bottom edges. This helps your model stick to the plate and makes it easy to take off.

Make sure vertical pins are thicker than 5mm. Add a rounded base to make them stronger.

Split up complicated models. This makes printing easier and uses less support.

Turn holes so they are vertical. This makes them more accurate and needs less support.

Think about which way your part will be printed. Fdm parts are not as strong up and down, so plan for that.

Use rounded edges and chamfers to make your part stronger and look better.

For tiny pins, print holes instead. Then use store-bought pins for more strength.

Try to use fewer supports by changing how your part sits or splitting it.

Keep the walls between 0.75 and 1.00 mm thick. Do not make overhangs more than 45°. Use brims or rafts to help your part stick and stop warping. Always check your model before you print.

ABS filament needs to be stored carefully. Put it in a sealed box with drying packs. Keep it cool, dry, and out of the sun. If you do not have the original bag, use a vacuum bag. Check the air with a hygrometer and keep it under 50%. Dry the filament if you hear popping or see it looks different when printing. Good storage stops warping, clogs, and bad prints.

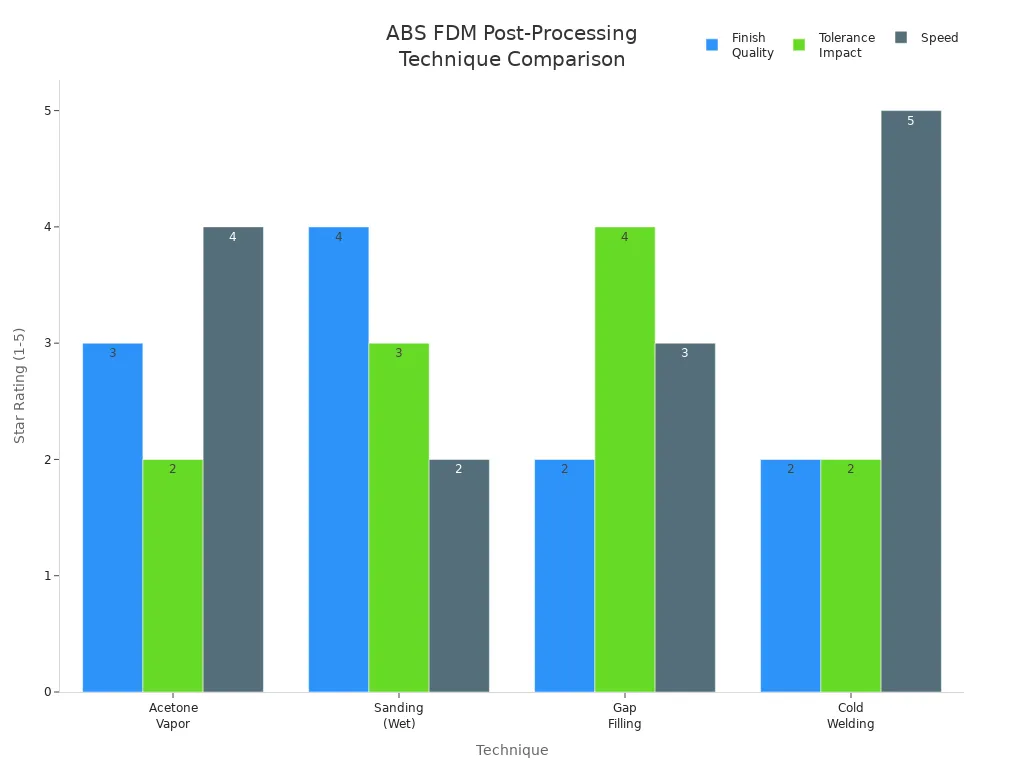

After printing, you can make your part look smooth and shiny. Acetone vapor smoothing works well for ABS. It makes the part glossy and hides the lines from printing. Sand the part with fine sandpaper to get it ready for paint or polish. Fill any gaps with ABS slurry or epoxy. You can also use acetone to glue parts together for a smooth finish.

Acetone vapor smoothing makes your part more water-resistant and tough. Be careful after smoothing because the surface is soft for a short time. Sanding and vapor smoothing together make your part look very professional.

Kaierwo’s fdm 3d printing service uses advanced fused deposition modeling. Their team knows how to get the best results with ABS and other materials. With lots of experience, Kaierwo helps you get strong, accurate parts for any project.

You want custom ABS parts fast. Kaierwo’s 3d printing service gives you that with fdm 3d printing. Their expert team helps you avoid design errors and get strong, accurate 3d parts. With 67% repeat customers, you know Kaierwo’s 3d printing and fdm work. Try their 3d printing for your next project.

Kaierwo’s fdm 3d printing:

No tooling needed for 3d parts

Fast 3d printing with fdm

Quality 3d printing checks

Easy 3d design changes

Trusted 3d printing experience

You upload your 3d model. The team reviews your design. You pick fdm or another 3d process. Kaierwo starts your 3d printing service right away.

Fdm gives you strong 3d abs parts fast. You get good detail and low cost. Fdm works well for prototypes and finished 3d models. Many people trust fdm.

Kaierwo uses advanced fdm machines for 3d abs parts. You get expert help, fast 3d turnaround, and strict privacy. Their 3d printing service supports many industries.

We attach great importance to customers' needs for product quality and rapid production.

We always insist that meeting customers' needs is to realize our value!