We attach great importance to customers' needs for product quality and rapid production.

We always insist that meeting customers' needs is to realize our value!

+86 133 9281 9446

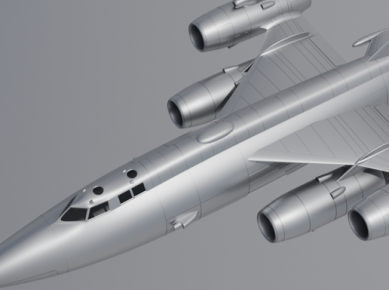

The aerospace industry requires extreme precision, reliability, and strict quality control. Components must meet demanding standards for strength, weight reduction, and dimensional accuracy.

Kaierwo provides CNC machining and manufacturing solutions for aerospace applications, supporting customers from prototype development to low-volume production with stable quality and engineering-driven processes.

Aluminum Alloys

Lightweight with excellent strength-to-weight ratio. Commonly used for structural components, housings, and aerospace frames.

Titanium Alloys

High strength, corrosion resistance, and excellent performance at elevated temperatures. Ideal for aerospace structural and load-bearing parts.

Stainless Steel

Provides durability and corrosion resistance. Suitable for brackets, fittings, and mechanical components requiring long-term stability.

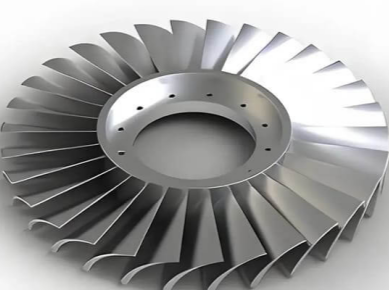

Inconel & Nickel Alloys

Designed for high-temperature and high-stress environments. Commonly applied in aerospace engine components and heat-resistant parts.

Carbon Fiber Composites

Ultra-lightweight with high stiffness. Used in structural components where weight reduction is critical.

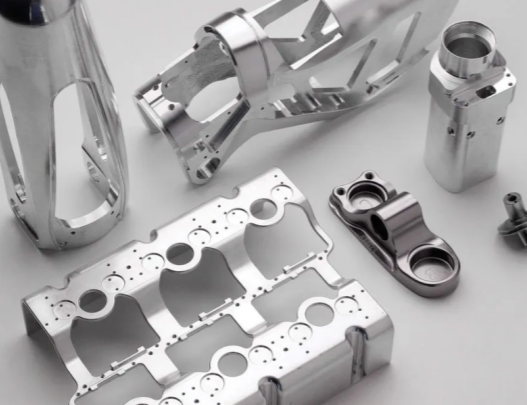

CNC Machining (Metal & Plastic)

Precision machining for aerospace structural parts, brackets, housings, and mechanical components with tight tolerances.

Functional prototypes for design verification, assembly checks, and performance testing.

Sheet metal parts for aerospace enclosures, panels, and lightweight structural components.

Processes to enhance corrosion resistance, durability, and surface quality.

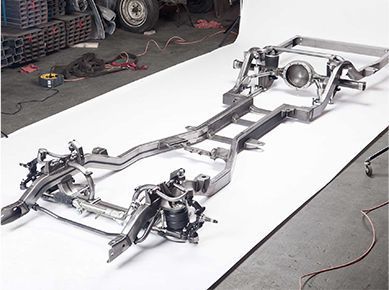

Structural brackets and frames

Aerospace housings and enclosures

Engine and heat-resistant components

Precision fittings and connectors

Lightweight structural parts

Custom aerospace mechanical components

Why Choose Kaierwo for Aerospace Manufacturing?

1.Engineering-Focused Manufacturing

Aerospace components require strict engineering validation from the very beginning. Kaierwo’s engineering team reviews part geometry, tolerances, material selection, and machining feasibility to ensure every component meets aerospace performance requirements. We focus on minimizing machining risks, improving structural reliability, and ensuring stable performance throughout the product lifecycle.

2.High Precision & Tight Tolerances

Precision is critical in aerospace manufacturing. Kaierwo utilizes advanced CNC equipment and proven machining processes to achieve tight tolerances and consistent dimensional accuracy. Our experience with complex geometries and multi-axis machining allows us to deliver parts that meet demanding aerospace standards.

3.Material & Process Expertise

We work with aerospace-grade materials including aluminum alloys, titanium, stainless steel, nickel-based alloys, and carbon fiber composites. Our team understands the machining challenges of hard-to-machine and heat-resistant materials, ensuring proper process control, surface integrity, and mechanical performance.

4.Strict Quality Control & Inspection

Quality assurance is a core part of our aerospace manufacturing process. Kaierwo follows standardized production workflows and performs thorough inspections using professional measuring equipment. Each part is carefully verified to meet drawing specifications, ensuring reliability, traceability, and repeatable quality.

Reviews

Aerospace Mechanical Engineer

“Kaierwo supported our aerospace project with CNC machining for precision structural components. The parts met our dimensional and tolerance requirements, and their engineering team was responsive during design review and production. Overall quality and delivery were consistent and reliable.”

Project Manager Aerospace Manufacturing Company

“We collaborated with Kaierwo on several custom aerospace components requiring tight tolerances and stable repeatability. Their machining capability, material handling, and inspection process gave us confidence throughout the project. Communication was professional and technically clear.”

Certifications

We use advanced metrology equipment to verify all incoming raw materials and will provide you full certificates of compliance for your peace of mind. Our metrology equipment includes Roughness, Vernier calipertester, Micrometer, etc. More information about our enquipment please read our page Quality Inspection. Our facility is fully certified to ISO13485:2016, ISO9001:2015, etc

1.OUR FACTORY VIDEO

More Industries we work with

Medical Devices

Transprent parts

Aluminum parts

We attach great importance to customers' needs for product quality and rapid production.

We always insist that meeting customers' needs is to realize our value!